Durmapress WC67Y 300T 3200 hydraulic press brake machine that export to Peru

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB,CIF |

| Payment Terms: | L/C, T/T, WU |

| Supply Ability: | about 400 set/month |

| Place of Origin: | Anhui |

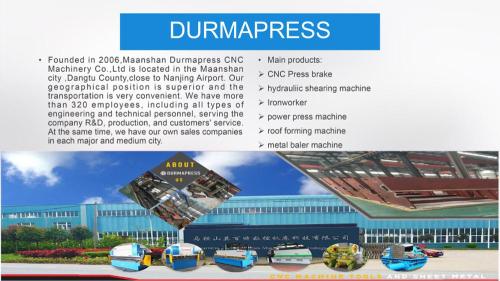

Company Profile

| Location: | Ma'anshan, Anhui, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

Product Detail

| Means of Transport: | Ocean, Land |

|---|---|

| Power: | Hydraulic |

| Raw Material: | Sheet / Plate Rolling |

| Machine Type: | Press Brake |

| Extra Services: | End Forming |

| Automation: | Manual |

| Certification: | CE |

| Material / Metal Processed: | Carbon Steel |

| Brand Name: | durmapress |

| Nominal force: | 3000KN |

| Worktable length: | 3200mm |

| Poles distance: | 2530mm |

| Throat depth: | 400mm |

| Stroke: | 250mm |

| Max open: | 590mm |

| Power: | 22KW |

| Dimension: | 3200*2000*3450mm |

| stanless steel: | 6mm |

| mild steel: | 12mm |

| Production Capacity: | about 400 set/month |

| Packing: | Wooden package of the both angle notcher |

| Delivery Date: | 30 days |

Product Description

Main Features:

1. Totally European design, streamlined looking,Monoblock,Welded steel frame

2. MTR PRESS BRAKE is Equipped with the Estun user-friendly user interface,the E21

provides all main press brake functionality.

3. Automatic tonnage and stroke adjustment for bending angles.

4. All tubes are connected by tube insertings to avoid oil lost and burst by welding tubes.

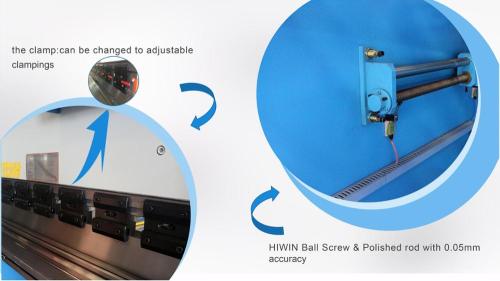

5. Ball screw and line guide was designed to improve precision.

6. E-Z fast wedge clamping was designed to change tools quickly.

7.Safe fence and the electric interlocker

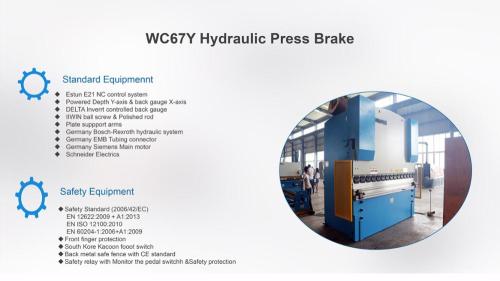

Standard Equipment:

1.System Intermediate Upper clamps with Anti Wedges

2.Plate Support Arms

3. Powered Depth Axis

4. Backstop

5. Light guards

6. Top and Bottom Tooling

7. Estun E21 NC control

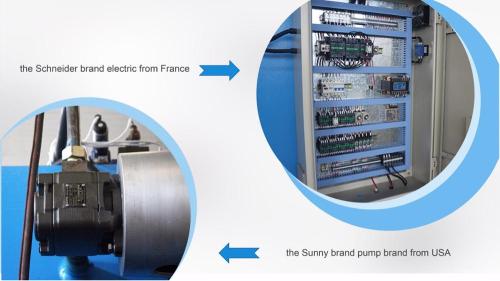

8. Germany Bosch-Rexroth Hydraulic

9. Telemecanique/SchneiderElectrics

10. Hydraulic and Electrical overload protection

11. Squaring Arm and Front Support Arms

12. Delta inverter with ball screw and polished rod with 0,05 mm accuracy.

13. Side guard is standard meeting CE regulations.

| SPECIFICATIONS FOR WC67K-300T/3200mm PRESS BRAKE | |

| Nominal force | 3000KN |

| Worktable length | 3200mm |

| Poles distance | 2530mm |

| Throat depth | 400mm |

| Stroke | 250mm |

| Max open | 590mm |

| Power | 22KW |

| Dimension | 3200*2000*3450 |

| mild steel | 12mm |

Performance:

1. The frame is steel-welded construction, vibrating to eliminate stress, with high strength

and good rigidity.

2. Forcing-torsion shaft maintains the synchronization of both cylinders with high precision.

3. Mechanic stop nuts ensure stable and reliable positioning accuracy.

4. The RAM is driven by hydraulic system with two cylinders. Working pressure could be

adjusted step less and the noise of machine is lower.

5. The stroke of RAM and back gauge could by adjusted through motor; Also it could be

adjusted by hand wheel for fine position. The value adjusted could be displayed on

numerator.

6. Main sliding parts such as cylinders, piston rod, guide way, are all treated with

wear-resistance.

7.There are slanting wedges (compensation units) installed on the top of tools. They

could be adjusted by hand to meet theaccuracy requirements of work piece.

8. Deflection compensation unit is adopted under worktable for the machine above 250

Tons.

9. Full machine is guarded with safety guard with inter locker to prevent the operator from

injured.

Quality and Service Assurance:

1.we have Q & C department in our factory and our engineer have much experience

and can design the suitable machine for our clients.

2.our machine can produce the nice production, can guarantee good quality.the

production is confirm to the national standard even the international standard

3.the products should not have scratch and the flatness

Technical R & D Department: design teams for different kind of production line.

package:

1.As to the roll forming machine's package, it should be nude.

2.we'll protect the machine well before shipment, to prevent machines from rusting

and damage.

Repairs:

Warranty: 1 year since the date of B / L on

Installation and Commissioning:. We will send professional engineers to buyers' country

for installation and commissioning Buyer pays each engineer 100USD / Day besides the

round-tickets, room and board.

RFQ

How about your machine quality?We are worry about the quality.

Durmapress is a mature brand in CHINA,through our many years research in technology,

our design including structure and detailed sercurity and precision has enhanced greatly,

and can match all the CE standard or more strict standard.Our machines distribute

worldwide to about 50 countries where there are metal plate industry ,there are

DURMAPRESS machines.And where there are our machines,there are good

reputation and terminal user satisfaction.

Whether the machine price can be more discount

Durmapress always provide high quality machine,as we know ,oversea market

is more important and difficult than domestic market because of communication

time costing after sales,So always,our machine has enough quality standard to

make sure the machine can work more than the real warranty period.In this way ,

we will save a lot and think in advance for the clients.

Actually Durmapress also think about our price level,we are sure to provide quality

=price and pice=quality ,the matched price and acceptable for the clients and

durable for our machines.We welcome your negotiate with us and get a good satisfaction.

How about your manufactory in CHINA

Durmapress located in MAANSHAN CITY,ANHUI province who is the leading area in

China and also in the worldwide as the center of the metal plate solution machines,

We have worked about 10 years in this area and totally have about 150 staffs.Rich

experience in this field with professional technical supporting and oriented service.

We welcome your visit to us any time.

Do you accept L/C payment term?

Yes,we accept 100% L/C at sign from almost all countries.