E21S Controller QC12Y 4X2500 Hydraulic Swing Beam Shearing Machine

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB,CIF |

| Payment Terms: | L/C, T/T, WU |

| Supply Ability: | 400 set month |

| Place of Origin: | Anhui |

Company Profile

| Location: | Ma'anshan, Anhui, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

Product Detail

| Model No.: | QC12Y-4*2500 |

|---|---|

| Means of Transport: | Ocean, Land |

| Power: | Hydraulic |

| Raw Material: | Sheet / Plate Rolling |

| Machine Type: | Pipe End Forming Machine |

| Extra Services: | End Forming |

| Automation: | Automatic |

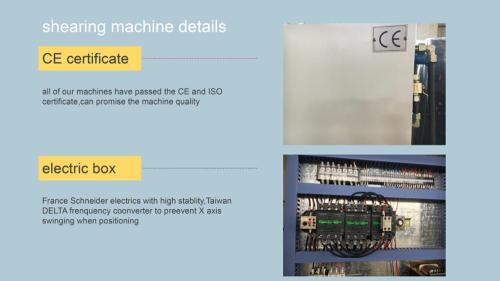

| Certification: | CE |

| Material / Metal Processed: | Carbon Steel |

| Brand Name: | DURMAPRESS |

| Cutting thickness: | 4mm |

| cutting width: | 2500mm |

| stopper adjust range: | 20-500mm |

| power: | 5.5KW |

| dimension: | 3040*1550*1550mm |

| Main Motor: | Siemens Germany |

| Siemens Germany: | Customer pointed |

| Warranty: | 5 years |

| Type: | Plate Shearing Machine price |

| Seal ring: | Valqua |

| Production Capacity: | 400 set month |

| Packing: | Wooden package of the both angle notcher |

| Delivery Date: | 30 days |

Product Description

.

Product Description

Production Details:

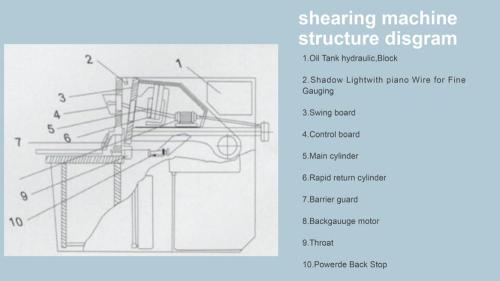

This shearing machine we also call swing beam shear machine. The machine is

hydraulically powered or mechanically. It works by first clamping the material with a ram,

A moving blade then comes down across a fixed blade to shear the material.

The workpiece material include aluminum, mild steel, stainless steel, galvanized sheet,

iron sheet, and so on.

1.Adjusting of the gap between blades is portable and quick. The value of the gap is

indicated on a dial.

2.Adopt advanced hydraulic system, reliable and easy for maintenance.

3.Meet with international safety standard.

4.Frame welded, vibration to eliminate stress, high in rigidity, sturdy and durable. Hydraulic

drive, swing beam, return of knife beam is smooth and prompt by accumulator or nitrogen

cylinder, stead&reliable performance.

5.The position of low blade can be adjusted to ensure the equilibrium of the gap after

regrinding. The portable and prompt adjusted of the blade's gap, the value of gap is

indicated by dial, positioning reliable.

6.The digital display devices used to the back gauge's value and the shearing times are

on the front of the machine.

2.Standard Equipment:

Estun E21s NC control system

Powered Back guage X-axis

DELTA Inverter controlled back gauge

HIWIN Ball screws&polished rod with 0.05mm accuracy

Squaring Arm and Front Support Arms

Germany EMB Tubing connector

Germany Bosch-Rexroth hydraulic

Germany Siemens main motor

Telemecanique/Schneider Electrics

Hydraulic &Electrocal overload protection

Cutting Line Illumination and wire for shadow line cutting

Top blade with two cutting edges and bottom blade with four cutting edges.(6CrW2Si)

3.Safety Equipment:

Safety Standards(2006/42/EC)

1.EN 12622:2009+a1:2003

2.EN ISO 12100:20110

3.EN 60204-1:2006+A1:2009

Front finger protection (Safety light curtain)

South Korea Kacon Foot Switch (Level 4 of safety)

Back metal safe fence with CE standard

Safety relay with Monitoor the pedal switch and safety protection

Hydraulic cnc 4mm small steel cutting machine/steel plate shearing machine

1. Sheet plate welded structure is adopted, with hydraulic transmission and accumulator

return, typical of an easy operation, reliable performance, and nice appearance, fitted with

digital display system.

2. Indication by indicator is provided for adjustment of blade clearance, for a handy and

prompt adjustment.

3. Alignment device with lighting and control device for shearing stroke are set, with a handy

and prompt adjustment.

4. Rolling material support ball is provided, to minimize fish tall with sheet bar and to reduce

frictional resistance.

5. The machine tool is provided with the function of digtal display, soft limit, as well as prompt

for one-way positioning clearance, and automatic counting for shearing.

6.The rear stopper is fitted with coder and digtal display system, so that the position of rear

stopper is displayed more accurately, thus to further enhance the shearing precision of this

machine.

7. Certification: ISO9001, SGS, CE;

FAQ

shearing machine price

Q: How to get a accurate quotation from us ?

A:Prvide us the details of material , such as metal thickness and width .

Q:You are manufacturer or trading company ?

A: We are 100% manufacturer with 17 year's manufaturer experience.

Q:Can you do OEM service ?

A:Yes, we can. your design is accepted , your own logo can be used on the machine.

Q:What's the shipping cost from china to your country ?

A:We can send machine to your port or door address by sea or airplane. please kindly tell us your nearest

port or address with postcode. we have reliable shipping agent to insure the safe convenient and time

delivery.

Q:Do you accept LC payment ?

A:Yes, normally our payment is 30%+70% ,LC payment is also acceptable

Q:How to operate this machine ?

A:Video line of our factory or we send you the moive directly.

Q:What about commissioning service ?

A: We can offer commissioning service , the buyer need to afford plane tickets.

Q:Do you offer teaching & training ?

A:Training at supplier's plant

Main Technology parameter for QC12Y/K-4x2500

| Model | QC12Y/K-4x2500 |

| Cutting Thickness | 4MM |

| Cutting Width | 2500MM |

| Cutting Angle | 1°30″ |

| Material Inten | ≤450kn/cm |

| Rear stopper adjusterme | 20-500 |

| Travel times | 10 |

| Hold downs | 12pcs |

| Weight | 3800kg |

| Dimension | 3040X1610X1620mm |

Our Certifications

Packaging & Shipping