hydraulic Servo Cnc Press Brake WC67k 100T4000 with AD52S

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB,CIF |

| Payment Terms: | L/C, T/T, WU |

| Supply Ability: | about 400 set/month |

| Place of Origin: | Anhui |

Company Profile

| Location: | Ma'anshan, Anhui, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

Product Detail

| Model No.: | wc67K-100t/4000 |

|---|---|

| Means of Transport: | Ocean, Land |

| Power: | Cnc |

| Raw Material: | Sheet / Plate Rolling |

| Machine Type: | Beading Machine |

| Extra Services: | End Forming |

| Automation: | Automatic |

| Certification: | CE |

| Material / Metal Processed: | Stainless Steel |

| Brand Name: | durmapress |

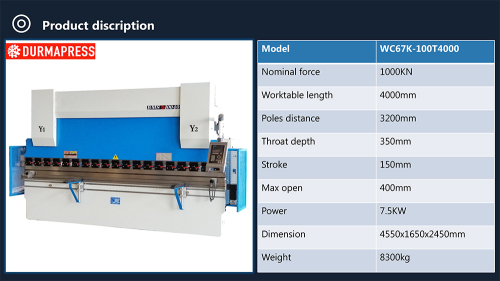

| Nominal force: | 1000KN |

| Worktable length: | 4000mm |

| Throat depth: | 320mm |

| Stroke: | 120mm |

| Poles distance: | 3000mm |

| Max open: | 370mm |

| Power: | 7.5KW |

| Dimension: | 4000*1600*2700mm |

| Weight: | 7400kg |

| mild steel: | 3mm |

| Production Capacity: | about 400 set/month |

| Packing: | Wooden package of the both angle notcher |

| Delivery Date: | 30 days |

Product Description

1. Main Features:

Brand-new industry design combined with modern aesthetic concept, high-quality production technology with simple appearance.

Latest high-frequency responding hydraulic control technology, faster, more efficient and higher accuracy.

Heat treatment of the machine frame, rigidity optimization verification on entire machine and the application of hydraulic compensation structure jointly ensure the bending precision of MB8 series Press Brakes.

Optimal ratio of parameters and top-level core configuration ensure stable performance, and easy operation.

MB8 standard 2axis backgauge system, as for complicated shape work piece, 4 or 5 axis backgauge system and corresponding dies are available for your option.

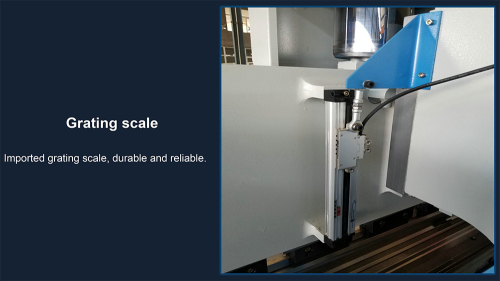

Press Brake using fully closed-loop electro-hydraulic servo control technology, slider position signals can be feedback to NC system by bilateral gratings, then NC system adjusts the amount of fuel tank by changing the synchronous valve opening size, hereby controlling the slider ( Y1,Y2 ) running on the same frequency, maintaining the parallel state of the worktable.

According to process state of sheet metal, CNC system can automatically control the table deflection compensation value resulting in uniform length and angle of all workpieces.

The use of hydraulic deflection compensation gives access to uniform full length workpieces. Hydraulic deflection compensation consists of a set of oil cylinders in the worktable, which can make the table occurs relative movement and form an ideal convex curve, ensuring the relative position relations with slider keep unchanged. Compensation values are subject to plate thickness and properties of material to be cut.

2 Main Configurations:

CNC system adopts Holland DELEM DA52S

Grating ruler controls depth of Y1 and Y2 axis(y1/y2-axis 0.01mm)

Servo motor servo drives control X axis(X, R-axis 0.01mm), stop finger can be easily moved along the cylindrical guide.

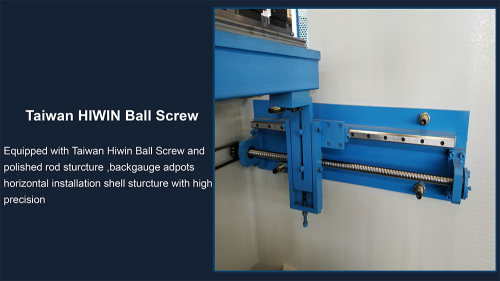

Keep the accuracy between HIWIN ball screw and linear guide rail within 0.01mm

Front supporter can be adjusted along the linear guide rail in the worktable direction

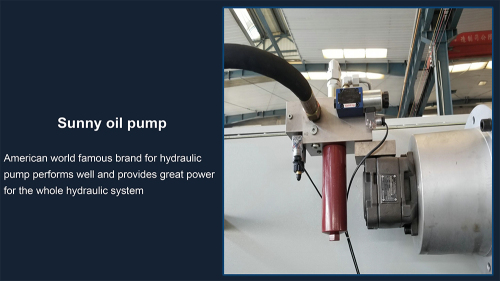

Germany Rexroth fully closed-loop electro-hydraulic servo synchronously controls the system

Germany EMB oil tube connectors

Germany Siemens main motor

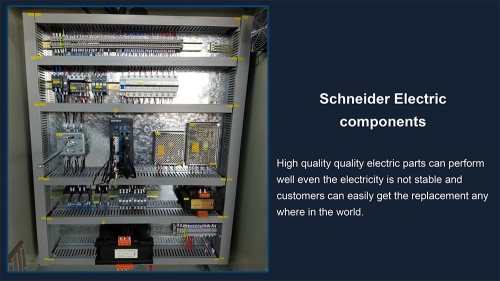

France Schneider Electrics

Hydraulic and electrical overload protection

Upper are mechanical fast pinching dies. Lower are double-V easy changeable dies

8″ broadband color display

Max 4-axes control (Y1, Y2, two additional axes )

266MHZ processor, memory capacity of 64M

Die library, 30 upper dies, 30 lower dies

USB memory interface, RS232 interface

Real-time Windows operating platform to ensure the stability of the operation, support instant shutdown

One-page parameters for rapid editing, navigation shortcut keys

Automatically calculate deflection compensation value

Micro switch panel, data editing

Automatically calculate the bending pressure and die safety region

Online operation analysis tool, Diagnostic Dashboard, angle calibration database

3. Holland Delem DA52S Controller:

RFQ

Q: How to get a accurate quotation from us ?

A:Prvide us the details of material , such as metal thickness and width .

Q:You are manufacturer or trading company ?

A: We are 100% manufacturer with 17 year's manufaturer experience.

Q:Can you do OEM service ?

A:Yes, we can. your design is accepted , your own logo can be used on the machine.

Q:What's the shipping cost from china to your country ?

A:We can send machine to your port or door address by sea or airplane. please kindly tell us your nearest port or address with postcode. we have reliable shipping agent to insure the safe convenient and time delivery.

Q:Do you accept LC payment ?

A:Yes, normally our payment is 30%+70% ,LC payment is also acceptable

Q:How to operate this machine ?

A:Video line of our factory or we send you the moive directly.

Q:What about commissioning service ?

A: We can offer commissioning service , the buyer need to afford plane tickets.

Q:Do you offer teaching & training ?

A:Training at supplier's plant