Q35Y with multifunctional punching bending cutting shearing notching Universal Hydraulic Ironworker

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB,CFR,CIF,DAT,FAS,DDP |

| Payment Terms: | Paypal, L/C, D/P, D/A, T/T, WU, Money Gram |

| Supply Ability: | 600 sets per year for hydraulic ironworker |

| Place of Origin: | Anhui |

Company Profile

| Location: | Ma'anshan, Anhui, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

Product Detail

| Model No.: | 90Ton ironworker |

|---|---|

| Means of Transport: | Ocean, Land |

| Brand Name: | Durmapress |

| Norminal pressure: | 90Ton |

| Voltage: | 380V/220V Optional |

| Name: | punching and shearing machine |

| Color: | gray and black,or by customer |

| Max. thickness cutting: | 20mm |

| 90 degree shearing: | 140x140x12mm |

| Throat depth: | 355mm |

| Max. punching diameter: | 20mm |

| Square bar: | 50x50mm |

| Round bar: | 50mm |

| Production Capacity: | 600 sets per year for hydraulic ironworker |

| Packing: | PVC film covered punching and shearing machine |

| Delivery Date: | Shipped in 7 days after payment |

Product Description

Product Description

Features

1. Cutting position of angle steel can be 45 degree cutting both from top and bottom

2. The diamond blades ensure high quality cutting, that is minimum variant and loss of cutting material. It can be 45 degree cutting both from top and bottom

3. Cutting position of round steel and square steel has several different size hole, adjustable fixing device is convenient for cutting different sizes steel

4. Optional blades

5. Adopt large nut and square stop plate to ensure precision

6. Adopt potection guarding to guarantee operation safety

Advantage of the machine

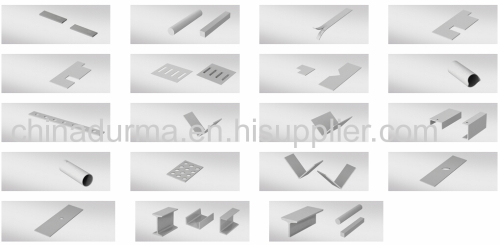

1.Q35Y Series Hydraulic Iron worker,Totally European design,the machine are strong and easy to use machines which are able to can cut and punch all kinds of materials such as plate,square bar,round bar,channel and so on.

2.Little Giant CNC industrial hydraulic iron workers have been designed and built to the highest quality standards in the industry.This profitable machine will serve any grueling fabrication shop for decades to come.

3.The machine by the European union CE certification and ISO quality system certification.

4.Adopt hydraulic drive,this series machine is suitable for the plastic material of blanking,drawing and pressing process.Such as sheet metal blanking, stretching, fine blanking,the cold extrusion of metal parts

5.Hydraulic transmission is the latest product of the multi-function joint punching and shearing machine,shearing punching,die cut flat steel,square steel,round steel,angle steel,channel steel,I-beam carried,and equipped with shear block feeding devices.

Attention

1.Punching and notching work should not be performed at the same time.

2.Keep all edges of blades sharp.

3.To ensure safe punching and cutting work the hold-down unit should be adjusted according to any thickness of material within the cutting capacity of the machine.

Features

1.Double-cylinder hydraulic punch & shear machine

2.Five independent stations for punching, shearing, notching, cutting and bending

3.Large punching table with multi-purpose bolster

4.Rear notching station, Low power inching and adjustable stroke at punching station

5.Centralised pressure lubrication system

6.Electric panel with overload protection elements and integrated controls

7.Safety movable foot pedal

Punching Full range of universal punches and dies are available. Unique style allows for large angle iron punching and large channel punching. Large viewing window on stripper swing away design for ease of operation. Large two piece gauging table with rulers and stop as standard fittings. Quick change coupling nut and sleeve for rapid replacement of change.

Shearing Round and square bar shear has multiple holes for a variety of sizes. Adjustable hold down device for round/square bar, channel/beam cutting. Large strong guarding for max safety.

The angle shear has the ability to cut angle at 45° Both top and bottom leg. This gives the operator the ability to make a picture frame corner for perfect welds. Diamond shaped blade for quality cuts that is minimal material lost and deformity.

Notching Unique design allows for cutting of angle and flat bar. Electrical interlock safety guard and three gauging stops for precise positioning.

Q35Y-20 Hydraulic Combined Punching and Shearing Machine Technical Parameters | |||

Model | Q35Y-20 | Trips Frequency(times/min) | 12-20 |

Punching Pressure (T) | 90T | Depth of Throat (mm) | 355 |

Max.Cutting Thickness of Steel Plates (mm) | 20 | Punch Depth (mm) | 22 |

Material Strength (N/mm²) | ≤450 | Max.Punching Diameter (mm) | 30 |

Angle of Shear (°) | 8° | Motor Power (KW) | 7.5 |

Flat Bar Shearing (T*W) (mm) | 20*330 10*480 | Overall Dimension ( L*W*H) (mm) | 1900*900*1950 |

Max.Length of Cylinder Stroke (mm) | 80 | Machine Weight (T) | 2.7 |