WC67Y cylinder box making machine cnc bending machine and folding machine

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB,CFR,CIF,DAT,FAS,DDP,DAP,CIP,CPT,FCA,EXW |

| Payment Terms: | Paypal, L/C, D/P, D/A, T/T, WU, Money Gram |

| Supply Ability: | 15 sets pet month of the 160ton press brake |

| Place of Origin: | Anhui |

Company Profile

| Location: | Ma'anshan, Anhui, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

Product Detail

| Means of Transport: | Ocean, Land |

|---|---|

| Power: | Hydraulic |

| Raw Material: | Sheet / Plate Rolling |

| Machine Type: | Press Brake |

| Extra Services: | End Forming |

| Automation: | Automatic |

| Certification: | CE |

| Material / Metal Processed: | Stainless Steel |

| Brand Name: | Durmapress |

| Norminal pressure: | 160KN |

| Warranty: | 3 Years |

| Bending thickness: | 6mm |

| Bending length: | 3200mm |

| System: | ESA 60 Control system |

| Process material: | stainless steel plate , metal plate |

| Type: | 160/3200 |

| Poles Distance: | 3100mm |

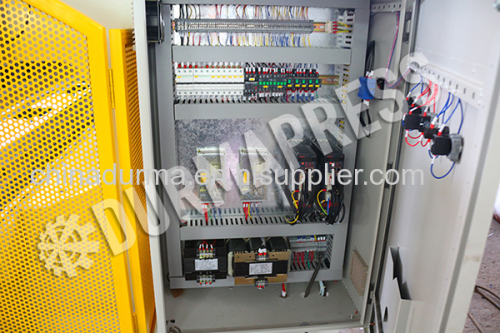

| Major Low voltage electrical: | Schneider |

| Name: | cnc press brake |

| Production Capacity: | 15 sets pet month of the 160ton press brake |

| Packing: | PVC films or wooden case |

| Delivery Date: | Shipped in 25 days after confirm |

Product Description

Hydraulic Sheet Metal Bending Press Brake Machine Price for Sheet Metal Bending

steel bending press brake machine

The whole machine is designed according to JB/T2257.2-92(China National standard) "plate bending machine technical conditions" and GB/T14349-93 "plate bending machine precision", all the parts of this machine are using computer graphics, computer element analysis, computer aided manufacturing, MC use CAD, CAE, CAM software for machine structure design, and fully guaranteed the structural strength enough and rigid of each machine component.

The whole steel frame welded structure, made the press brake thick, high rigidity, strong shock anti-knock.

The mechanical structure of the machine is mainly composed of a frame, a worktable, a ram, a main oil cylinder and the rear stopper, etc. With perfect design and improved the manufacturing processing, we can effectively guarantee the accuracy of the machine manufacturing and using.

For the WC67Y/K steel bending press brake machine, besides the above models, we accept customizing accordingly.

Plz advise the plate material, length and thickness, we will design the steel bending press brake machine for you.

WC67Y/K NC/CNC press brake machine

WC67Y cylinder box making machine cnc bending machine, 3d metal cnc machines press brake, cnc metal folding machine

Model WC67Y | Nominal Pressure | Length of Working Table | Distance between uprights | Throat depth | Ram Stroke | Main Motor Power |

(kn) | (mm) | (mm) | (mm) | (mm) | (kw) | |

63/2500 | 630 | 2500 | 2020 | 250 | 120 | 5.5 |

63/3200 | 630 | 3200 | 2520 | 250 | 120 | 5.5 |

80/3200 | 800 | 3200 | 3020 | 320 | 120 | 7.5 |

100/3200 | 1000 | 3200 | 2520 | 320 | 120 | 7.5 |

125/4000 | 1250 | 4000 | 3020 | 400 | 120 | 7.5 |

160/3200 | 1600 | 3200 | 2520 | 320 | 200 | 11 |

160/6000 | 1600 | 6000 | 4850 | 400 | 200 | 15 |

200/4000 | 2000 | 4000 | 3020 | 400 | 200 | 15 |

200/6000 | 2000 | 6000 | 4850 | 400 | 200 | 15 |

250/3200 | 2500 | 3200 | 2520 | 400 | 250 | 18.5 |

250/4000 | 2500 | 4000 | 3020 | 400 | 250 | 18.5 |

300/4000 | 3000 | 4000 | 3020 | 400 | 250 | 22 |

300/6000 | 3000 | 6000 | 4850 | 400 | 250 | 22 |

400/6000 | 4000 | 6000 | 4850 | 400 | 250 | 30 |

500/6000 | 5000 | 6000 | 4850 | 400 | 300 | 37 |

600/7000 | 6000 | 7000 | 5600 | 400 | 300 | 45 |

1000/8000 | 10000 | 8000 | 6000 | 500 | 450 | 2*37 |

We use the famouse brands for steel bending press brake machine configurations, smoothly bending effect, good quality and high performance.

No. | Item | Quantity | Brand |

| 1 | Motor | 1Set | Siemens Germany |

| 2 | Gear pump | 1Set | Sunny USA |

| 3 | Casting connector | 1Set | Cast CO Italy |

| 4 | Main electric parts | 1Set | Siemens Germany & Schneider France |

| 5 | 1Set | Rexroth Germany | |

| 6 | Sealing rings | 1Set | Valqua CO Japan |

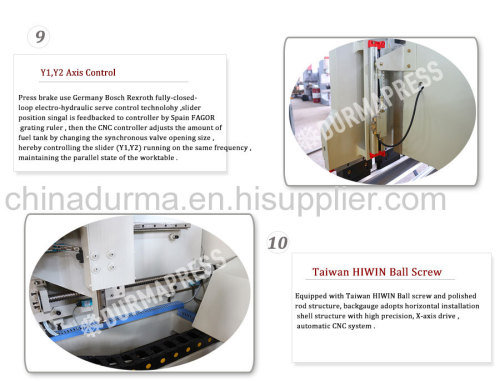

| 7 | Ball screw and line guide | 1Set | Hiwin Taiwan China |

| 8 | Conrol System | 1Set | Estun or Delem or ESA or Cybelec or according to client's requirement |

1.Installation

Free installation and commissioning, travel expense is on foreign customer.(Including round ticket and accommodation cost)

2.Personnel training

Free training for about one week.

3. After-sale service

One year warranty.During warranty period,free maintenance service can be provided.(except man-made faults or damages arising from irresistible natural factors)