WC67K 160Ton cnc hydraulic used press brake

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB,CFR,CIF,DAT,FAS,DDP,DAP,CIP,CPT,FCA,EXW |

| Payment Terms: | Paypal, L/C, D/P, D/A, T/T, WU, Money Gram |

| Supply Ability: | 15 sets pet month of the 160ton press brake |

| Place of Origin: | Anhui |

Company Profile

| Location: | Ma'anshan, Anhui, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

Product Detail

| Model No.: | WC67K-160T4000 |

|---|---|

| Means of Transport: | Ocean, Land |

| Power: | Hydraulic |

| Raw Material: | Sheet / Plate Rolling |

| Machine Type: | Press Brake |

| Extra Services: | End Forming |

| Automation: | Automatic |

| Certification: | CE |

| Material / Metal Processed: | Stainless Steel |

| Brand Name: | Durmapress |

| Norminal pressure: | 160KN |

| Warranty: | 3 Years |

| Bending thickness: | 6mm |

| Bending length: | 4000mm |

| System: | DA52S Control system |

| Process material: | stainless steel plate , metal plate |

| Type: | 160/4000 |

| Poles Distance: | 3500mm |

| Major Low voltage electrical: | Schneider |

| Name: | cnc press brake |

| Production Capacity: | 15 sets pet month of the 160ton press brake |

| Packing: | plastic packing and fixed in the container |

| Delivery Date: | Shipped in 25 days after confirm |

Product Description

First:Technical Data

| No. | Specification | Value | Unit |

| 1 | Nominal pressure | 1600 | KN |

| 2 | Length of working table | 4200 | mm |

| 3 | Distance between uprights | 3090 | mm |

| 4 | Throat depths | 400 | mm |

| 5 | Stroke | 250 | mm |

| 6 | Open height | 500 | mm |

| 7 | Motor power | 18.5 | Kw |

| 8 | Overall dimension | 4400×1900×2900 | mm |

| 9 | Weight | 16000 | Kg |

Second:Specification

1.Steel welded structure, stress elimination by vibration, high mechanical strength, and exceptional rigidity.

2.Hydraulic top-drive, steady and reliable.

3.Mechanical stop and steel torsion bar to maintain synchronization and high precision.

4.Electric adjustment, manual fine adjustment, and digital display for backgauge distance and stroke of up ram.

5.Deflection compensation unit installed on the up die or on the down die if the operating pressure is 63t or above.

6.Safe fence and the electric interlocker have been designed for the machine to ensure the operation safety.

7.The drive element of backgauge adopts imported ball screw and linear guideway.

8.The equipment automatic hydraulic crowning system can compensate the bending tolerance caused by the ram torsion.

9.Electric box:power off when open the door.

Third:Stndard export equipments

| No. | Item | Remark |

| 1 | Motor | Siemens beide(China) |

| 2 | Gear pump | Chengjie(China) |

| 3 | Casting connector | Cast.o(Italy) |

| 4 | Main electric parts | Siemens(Germany) |

| 5 | Hydraulic system | Rexroth(Germany) |

| 6 | Sealing rings | Valqua CO.(Japan) |

| 7 | Linear bearing rod | KBS(Hangzhou,China) |

| 8 | Ball screw and line guide | Hiwin(Taiwan,China) |

| 9 | E21 DRO | Estun(China) |

If you ask for CNC control system,we have E200,DA41,DA52 to choose from.

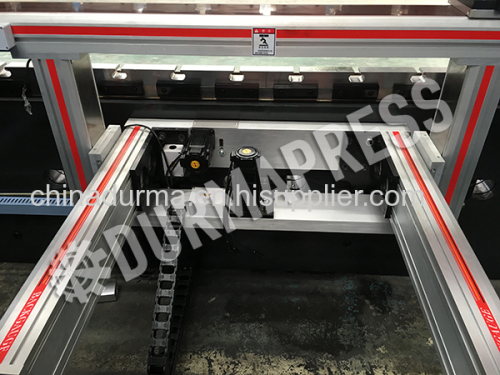

Four:Pictures of machines and factory

cnc hydraulic Press brake Hydraulic system:

-A complete electrolyte servo synchro CNC (Computer Numerical Control) controlled press brake.

-Adopt Bosch electro hydraulic servo system (from Germany)

Mechanical system:

- Two light rulers are installed at the two ends of the slide, making the slide movement be parallel to the working table

- Adopt the working table compensation structure.

- The CNC servo motor of the back gauge gives a high positioning accuracy.

cnc hydraulic Press brake CNC system:

-Programming of the axes positions in tabular mode with automatic syntactical checks, automatic calculation of the bending and bending tonnage.

- All programs, tools description, parameters can be stored on the internal memory or on USB memory stick.

These files can be exchanged with other CNC and PC troughUSB memory stick.

- Complete graphic off-line programming on a standard PC, through a simulation program.

- Customizable alarm messages.

cnc hydraulic Press brake Synchro control system:

-Two light rulers (Y1-Y2) have been installed at the two sides of the machine to measure the exact distances.

-The position data will be delivered to the CNC system and then it can check out the servo valve control signal (S2-S2).