WC67K 160T/4000 4 axis cnc sheet metal bending machine cnc press brake

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB,CFR,CIF,DAT,FAS,DDP,DAP,CIP,CPT,FCA,EXW |

| Payment Terms: | Paypal, L/C, D/P, D/A, T/T, WU, Money Gram |

| Supply Ability: | 15 sets pet month of the 160ton press brake |

| Place of Origin: | Anhui |

Company Profile

| Location: | Ma'anshan, Anhui, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

Product Detail

| Model No.: | WC67K-160T3200 |

|---|---|

| Means of Transport: | Ocean, Land |

| Power: | Hydraulic |

| Raw Material: | Sheet / Plate Rolling |

| Machine Type: | Press Brake |

| Extra Services: | End Forming |

| Automation: | Automatic |

| Certification: | CE |

| Material / Metal Processed: | Stainless Steel |

| Brand Name: | Durmapress |

| Norminal pressure: | 160KN |

| Warranty: | 3 Years |

| Bending thickness: | 6mm |

| Bending length: | 4000mm |

| System: | DA52S Control system |

| Process material: | stainless steel plate , metal plate |

| Type: | 160/4000 |

| Poles Distance: | 3500mm |

| Major Low voltage electrical: | Schneider |

| Name: | cnc press brake |

| Production Capacity: | 15 sets pet month of the 160ton press brake |

| Packing: | plastic packing and fixed in the container |

| Delivery Date: | Shipped in 25 days after confirm |

Product Description

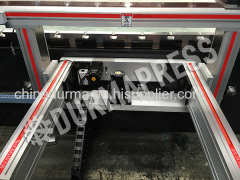

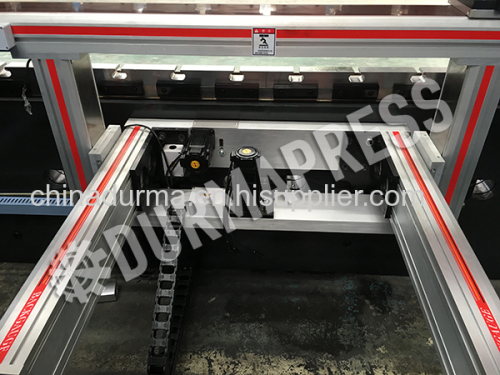

WC67K 160T/4000 6+1 axis cnc sheet metal bending machine , hydraulic bending machine cnc press brake

1. Standard Equipment:

Delem DA52S CNC control System

Powered Depth Y1-axis&Y2-axis&X-axis&V-axis&Back gauge X-axis (X-axis 0.01mm/Y1/Y2-axis 0.01mm)

Servo motor control block

HIWIN Ball screws & Polished rod with 0,01mm accuracy

Plate Support Arms

Germany Bosch-Rexroth Hydraulic

Germany EMB Tubing connector

Germany Siemens Main Motor

Tele mecanique/Schneider Electrics

Hydraulic &Electrical overload protection

Top and Bottom Tooling(86°,R0.6mm)

Safety Standards(2006/42/EC):

Front finger Protection(Safety light curtain)

South Korea Kacon Foot Switch(Level 4 of safety)

Back metal safe fence with CE standards

Safety relay with Monitor the pedal switch and safety protection

The compact DA-52s is a complete CNC solution for conventional as well as synchronised press brakes.

The panel based control, capable of controlling up to 4 axes, can be integrated in cabinets as well as in an optional pendulant arm housing.

Equipped with the Delem user-friendly user interface, the DA-52s provides all main press brake functionality.

The unique 'hotkey' navigation gives direct access to the programs in memory and enables quick and easy programming of a product. All common bend parameters are located on one page. For advanced parameters an additional page can be selected.

Angle programming of the Y-axis, crowning function and pressure control are standard on board.

USB interfacing enables the use of memory sticks as a fast product and tool backup medium.Quick, one page programming

Hotkey navigation

7" VGA colour TFT

Up to 4 axes (Y1, Y2, and 2 auxiliary axes)

Crowning control

Tool/material/product library

USB, peripheral interfacing

Advanced Y-axis control algorithms for closed loop as well as open loop valves

2. Safety Equipment:

1.EN 12622:2009 + A1:2013 2.EN ISO 12100:2010 3.EN 60204-1:2006+A1:2009

3. Delem DA52S CNC Control system:

DA-52S features

Totally EU streamlined design,Monoblock by welding robots & aparatus and stress relief process by Annealing treatment.

Hydraulic synchronised positive stop design,and by DELEM programmable controller assuring accurate repeatability &ease of use.

Integrated hydraulic system(Bosch-Rexroth form Germany)allowing rapid approach switching automatically to slow bend.

Servo drive with da52s System operated back gauge with quality support fingers also with vertical adjustment

Inch, single mode being designed for the machine and servo and maintain time can be controlled by the server Driver.

the distance of upper slide moving down is adjusted by grating ruler with high precision

Safe fence and the electric inter locker have been designed for the machine to ensure the operation safety.

PRODUCT FEATURE

1. The CNC steel sheet bending machine is used for bending or curving the flat sheet into arc shape sheet, and the bending radius of the colored steel sheet: R=1.8m.

2. Minimum Diameter: 1.2m.

3.Raw material thickness: 0.3--0.7mm, or as you require

3. Speed of Arc Line: L=13.5m/min.

4. Raw material width and length: under clents requirements.

MAIN TECHNICAL SPECIFICATION

1. Size: 2200mm × 1500mm × 1700mm

2. total weight: about1800KG

3. controlling system: PLC

4. power: 2.2KW

5. working speed:10--12m/min(adjustable)

6.Control: PLC computer control ( frequency converter)