CNC Press Brake press break machine Hydraulic press brake

| Min. Order: | 1 Set/Sets |

|---|---|

| Payment Terms: | L/C, T/T, WU |

| Supply Ability: | about 400 set/month |

| Place of Origin: | Anhui |

Company Profile

| Location: | Ma'anshan, Anhui, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

Product Detail

| Model No.: | WC67Y-125T/4000 |

|---|---|

| Means of Transport: | Ocean, Land |

| Power: | Hydraulic |

| Raw Material: | Sheet / Plate Rolling |

| Machine Type: | Press Brake |

| Extra Services: | End Forming |

| Automation: | Manual |

| Certification: | CE |

| Material / Metal Processed: | Carbon Steel |

| Brand Name: | durmapress |

| Nominal force: | 1250KN |

| Worktable length: | 4000mm |

| Poles distance: | 3000mm |

| Throat depth: | 320mm |

| Stroke: | 120mm |

| Max open: | 370mm |

| Power: | 7.5KW |

| Dimension: | 4000*1600*2700 |

| stanless steel: | 2mm |

| mild steel: | 4mm |

| Production Capacity: | about 400 set/month |

| Packing: | Wooden package of the both angle notcher |

| Delivery Date: | 30 days |

Product Description

PRoduct Application

The DURMAPRESS® CNC Press Brake, engineered with great care for details, is a high quality machine tool. The studies made on the framework flections have allowed us to design a product that reacts in the most appropriate and responsive way to the mechanical solicitations, therefore guaranteeing a stable structure, thus a higher precision in bending. This feature is even enhanced by a system of automatic crowning. Worth mentioning is also the possibility to add options and upgrades on the configuration, at later stage.

DURMAPRESS® Press Brakes are known for their precision and reliability: today these characteristics are joined by the high technological options such as the virtual bend software, the thickness measurement system and robot based automation. In the new era of modern press brakes, all of these bends can be done without operator intervention, without tools, without any slowing down of the bending process…

Produtivity:

- Automatic calculation of angle, force and back gauge axis.

- User-friendly control

- High performances

Versatility:

- Swaybend system (DURMAPRESS

- Configuration to the customer

Precision:

- Structural compensation system

- Servo-motorized axis

- Proporcional hydraulics

Safety:

- Machines with directive CE 2006/95 CE

- Lazer safety device

Reliability:

DURMAPRESS® has a strict policy for the choice of its components, on the basis of an extensive experience acquired over decades. All components are certified in accordance with European standards and their main sources are Germany, USA, Holland, Italy and Switzerland. All structural parts are calculated by the finite element method and only high quality steel S275 and S355 JR namely J2 (+ N) is used.

Main Features.

The frame is heavy-duty as well as compact and it assures precise results.It is made of high quality mild steel and it has undergone systematicmechanical processes.

• Electric welding of high precision

• Usage of high-tech boring machines for extreme precision parts

DURMAPRESS® chooses the best products to guarantee long-lasting and high-techmachines.

DURMAPRESS® selects the best components.

• Graphic color CNC

• Laser beam safety photocells

• Silent and reliable internal gear pump

• Hydraulic system regulated by proportional valves

• Combination of brushless drive and motor with "can open" digital technology, high precision backgauge which permits permits fast movements of the axes.

• High precision optical lines

• Adjustable clampings

• Hardened, grinded tools and clamps for quick tools adjustment

• Complete backgauge fingers on double linear guide with LEDs

• Stainless steel front supports adjustable in height

• Automatic hydraulic crowning

• Electrical panel with high quality components

• Start&Stop system

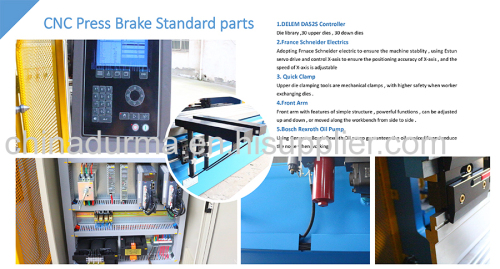

| Delem DA52s CNC Press Brake Control system: |

| 1. 6,4" VGA colour LCD (TFT) |

| 2. Numerical, one page programming |

| 3. Quick, one-page programming |

| 4. Up to 4 axes (Y1, Y2, and 2 auxiliary axes) |

| 5. CNC Crowning control |

| 6. USB, peripheral interfacing |

| 7. Tool/material/product library |

| 8. Servo, frequency inverter and AC control for backgauge axes. |

| The best bending results You can bend longer and deeper parts with standard SC/MB8-Bend Series. |