4 AXIS CNC Hydraulic press brake machine with Delem system

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB,CFR,DAT,FAS,DDP,DAP,CIP,CPT,FCA,EXW |

| Payment Terms: | Paypal, L/C, D/P, D/A, T/T, WU, Money Gram |

| Supply Ability: | 20 sets pet month of the 80ton press brake |

| Place of Origin: | Anhui |

Company Profile

| Location: | Ma'anshan, Anhui, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

Product Detail

| Model No.: | WC67K-80T2500 |

|---|---|

| Means of Transport: | Ocean, Land |

| Power: | Hydraulic |

| Raw Material: | Sheet / Plate Rolling |

| Machine Type: | Press Brake |

| Extra Services: | End Forming |

| Automation: | Automatic |

| Certification: | CE |

| Material / Metal Processed: | Stainless Steel |

| Brand Name: | Durmapress |

| Norminal pressure: | 800KN |

| Warranty: | 3 Years |

| Bending thickness: | 4mm |

| Bending length: | 2500mm |

| System: | E21 NC Control system |

| Process material: | stainless steel plate , metal plate |

| Type: | 80/2500 |

| Poles Distance: | 1800mm |

| Major Low voltage electrical: | Schneider |

| Name: | cnc press brake |

| Production Capacity: | 20 sets pet month of the 80ton press brake |

| Packing: | plastic packing and fixed in the container |

| Delivery Date: | Shipped in 25 days after confirm |

Product Description

ü THE STANDARD COMPONENTS |

1. DELEM DA52 CNC SYSTEM 2. SIEMENS OR SCHNEIDER ELECTRONIC ELEMENTS 3. USA PARKER SEAL 4. GERMANY REXORTH HYDRAULIC SYSTEM.ELECTRONIC-HYDRAULIC SYNCHRONIZATION PROPORTION VALVE. 5. GERMANY ECKERLE OR CHINA YONGSHUN 6. SIEMENS MOTOR or CHINA FAR EAST Motor 7. CHINA JIANHU CYLINDER HAS CHROMATE TREATMETN 8. PUNCH AND DIES: T8A 9. SECTION PUNCH AND DIES AVAIALABE IF THE CLIENT NEEDS SMALL SLIP PUNCH BENDING 10. BACK-GAUGE: 4 AXIS BACKGAUGE 11. PIPES : ANTI-RUST PHOSPHORIZATION PIPES WITH BOTH INSIDE AND OUTSIDE ANTI-RUST TREATED 12. PIPE CONNECTOR: HIGH QUALITY CONNCTOR FROM SHANGHAI COMPANY WITH HIGH QUALTY SEAL INSIDE TO PREVEND THE LEAKAGE OF THE HYDRAULC OIL. 13. REAR DOOR WITH OPEN-DOOR POWER-OFF FUNCTION FOR SECURITY 14. BOTH ENTRANCE AND EXIST OF THE HYDRAULIC OIL TANK, FILTER IS EQUIPPED. 15. MECHANICAL PUNCH RELEASE CLAMP 16. LIGH CURTIAIN 800MM 17. STANDARD AXIS: Y1/Y2/X+V AXIS (3+1 AXIS) 18. GRATING RULER: ITALY GIVI 19. SEVER MOTO: CHINA ESTUN

|

n HYDRAULIC SYSTEM |

1. USE GERMANY REXROTH PROPORTIONAL SERVO VALVE AND REACH HIGH SYNCHRONIZATION CONTROL PRECISION 2. MACHNE CAN WORK CONTINUOUSLY UNDER RATED BURDEN ,HYDRAULIC SYSTEM WITHOUT LEAKAGE ,STABLE AND HIGH PRECISION |

n ELECTRICAL CONTROL SYSTEM |

1. Electrical Cabinet under the standard of IP65, Electronic components under international CE Standard, safe and reliable, strong anti interference capability. 2. Movable hands safety pedal switch with the emergency stop function. |

n SYNCHRONIZATION CONTROL OF THE MAIN CYLINDER |

Two Main Cylinder's movement and position are controlled by Y1 and Y2 Axis,Y1 and Y2 are two separately parameter of CNC Control system. Tow sides of the machine configure two imported grating ruler to calculate the real distance between the ram and working table. Grating rulers are equipped a small rack in the connection of the working table to eliminate the influence of the ram location caused by the upright column deformation. When the slider is moving, the position digital details will feedback into CNC System, so the Servo valve control signal S1 and S2 will be calculated and output and control the output flow of the two servo valve to make sure the left and right main cylinder will working synchronization from beginning to end and will guarantee the high speed and position precision of the slider when working |

n THE V AXIS (MOTOR –CROWNING) |

DELEM DNC 60 SYSTEM BOTH IN TORSION BAR AND SYNCHRONZIAITON PRESS BKAKE , CAN CONTROL AND CALCULATE AUTOMATICAL COMPENSATION FOR WORKING TABLE. WE RECOMMEND THIS IF THE WORKING TABLE IS MORE THAN 3000MM.

CNC System V Axis control cylinder to reach the compensation. The CNC system can automatically reach the working table deflection compensation according to the loading situation.

|

n BACKGAUGE |

Accurate backgauge's backwards and forwards motion is controlled by X axis, the imported ball screw and liner guide rail are used with high precision, high-rigidity, fast-speed, strong-carrying capability. |

ü OPTIONAL COMPONENTS |

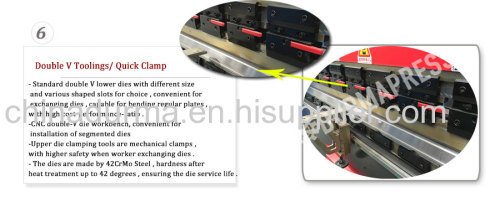

1. SECTION PUNCH AND DIES –PLEASE PROVIDE US THE DIMENSION IF NEEDED 2. FAST RELEASED CLAMP---USD600/SET MACHINE,WE HAVE INCLUDED THIS INTO THE PRICE. 3. BALL SCREW BACKGAUGE FINGERS---USD250/SET MACHINE INCLUDED ALREADY. 4. EUROPAN SNGILE V DESIGN IS POSSIBLE, SINGLE V IS OPPOSITE TO THE MULTI V (YOU CAN CHECK OUT MULTI V AT THE STANDRAD PUNCH AND DIES ARTICLE BELOW. MULTI V MEANS HAS SEVEARL V IN DIFFERENT SIDE) SINGLE V IS POPULAR IN EUROPEAN ,BUT SHOULD CALCULATE THE THICKNESS FIRSTLY FOR THE METAL PLATE TO MADE A DECISION. NORMALLY MULTI V IS BETTER IN USAGE TO SETTLE DIFFERENT THICKNESS PLATE BENDING SOLUTION. 5. MOTOR-CRWONG (V COMPENSATION AXIS ) IS INCLUDED. IF NOT NEEDED,PLEASE LET US KNOW ALSO. WE RECOMMEND TO USE. WE WILL EXPLAIN V AXIS COMPENSATION BELOW. 6. LASER LIGHT SECURITY PROTECTOIN IF NEEDED |

ü DELEM DNC 60 SYSTEM |

1. DELEM DA52 CAN CONTROL Y1/Y2/X+V AXIS 3+1 AXIS 2. THE CONTROL ELECTRONIC-HYDRAULIC SYNCHRONIZATION 7. THROUGH GRATING RULER AND THE SERVO MOTOR TO GET THE SINGEL WITH THE TWO CYLINDER 8. HAS THE ANGLE BENDING FUNCTION, THE Y/X/R+V AXIS CAN AUTOMATICALLY CALCULATED BY SET INTO THE ANGLE NEEDED 9. SET INTO THE SYSTEM PUNCH,DIES,STROKE SPECIFAICATION ,ALL THE OTHER STEPS WILL BE CALCULATED DIRECTLY 10. CAN CALCULATE STAINLESS STEEL,CARBON STEEL ,ALUMIIUM ITSELF 11. POSSIBLE TO MAKE ANGLE CORRECTION FUNCTION 12. CAN USE USB TO PUT INTO THE DRAWED CAD ,THE MACHINE SYSTEM CAN READ AND WORK DIRECTLY. 13. WORLDWIDE POPULAR CONTROL SYSTEM 14. OPERATION MANUAL IS AVAILABE 15. ELECTRONIC DRAWING IS AVAILABE 16. HYDRAULIC SYSTEM DRAWING IS AVIABLE 17. WE CAN DEPATCH OUR ENGINEER FROM UK TO TRAIN YOU IF NEEDE,THE SALARY WILL BE PAID BY BUYER. |

How about your machine quality?We are worry about the quality.

| |

Whether the machine price can be more discount

| |

How about your manufactory in CHINA

|