630KN CNC PRESS BRAKE WITH 2 AXES

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB,CFR,CIF,DAT,FAS,DDP,DAP,CIP,CPT,FCA,EXW |

| Payment Terms: | Paypal, L/C, D/P, D/A, T/T, WU, Money Gram |

| Supply Ability: | 50 SETS PER MONTH |

| Place of Origin: | Anhui |

Company Profile

| Location: | Ma'anshan, Anhui, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

Product Detail

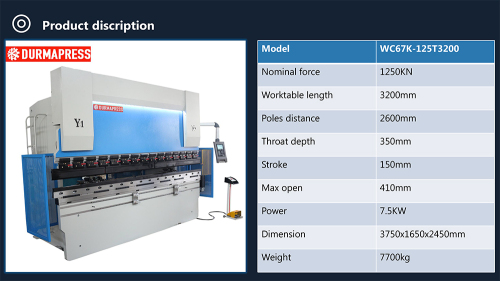

| Model No.: | WC67K-125T3200 |

|---|---|

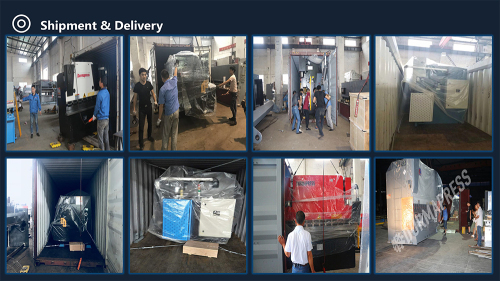

| Means of Transport: | Ocean, Land |

| Power: | Cnc |

| Raw Material: | Sheet / Plate Rolling |

| Machine Type: | Press Brake |

| Extra Services: | Machining |

| Automation: | Automatic |

| Certification: | CE |

| Material / Metal Processed: | Stainless Steel |

| Brand Name: | Durmapress |

| Normal pressure: | 1250KN |

| Bending width: | 3200mm |

| Machine Type: | Bending Machine |

| Brand Name: | DURMAPRESS |

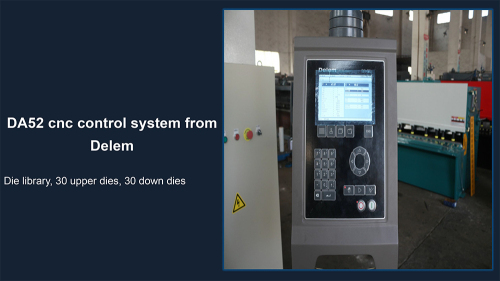

| Controller: | DA52 cnc Control system |

| Power: | Cnc |

| Voltage: | 220V/380V/415V/440V/customized |

| Color: | Customized |

| Warranty: | 2 Years |

| Production Capacity: | 50 SETS PER MONTH |

| Packing: | suitable for seaway and railway |

| Delivery Date: | 20 workings days |

Product Description

The whole structure of the hydraulic press brake:

Welded structure: the stress of the welded parts can be eliminated by vibration; so this forging press gives high accuracy.

Frame: consists of right and left wall boards, working table, oil box, slot steel and etc. The stress of the welded parts can be eliminated by vibration. The machine enjoys high accuracy and high strength and can be transported easily.

High accuracy,high efficiency,simple and convenient operation,good performance, favorable price and best service.

Main Features

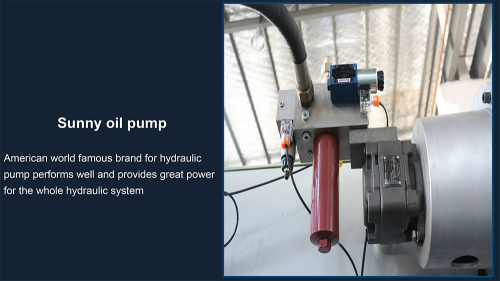

1) hydraulic drive, the machine at both ends of the cylinder placed in the slider, direct drive sliding work.

(2) the use of mechanical block structure, stable and reliable.

(3) slider stroke maneuver fast tune, manual fine-tuning, counter display.

(4) the use of all welded structure, with sufficient strength and rigidity.

(5) The slider synchronization mechanism uses the torsion axis forcing synchronization.

(6) wedge-shaped deflection compensation mechanism to ensure a higher bending accuracy

Main Configuration

Estun E21 controller

Controller controls and adjusts Y-axis and X-axis

Servo drive and control positioning of X-axis and Y-axis

Adopting HIWIN ball screw and linear guide rail, accuracy 0.05mm

Front supporter bracket

Germany Bosch Rexroth hydraulic valve block

Germany EMB oil tube connector

Germany Siemens main motor

France Schneider electrics

Hydraulic & electrical overload protection

Upper and lower dies(86°, R0.6mm, material: 42CrMo)

FAQ

1, Q: Are you factory or trading company?

A: We are factory of rolling machine, bending machine and shearing machine, factory was established in 2001, with more than 15 years producing experience.

2, Q: What's your payment?

A: T/T, 30% deposit in advance, 70% balance before ship.

Irrevocable L/C at sight

3, Q: What's about delivery time?

A: For small model press brake, usually 15-20 days after received 30% deposit.

For big model press brake, usually 30-45 days after received 30% deposit.

4, Q: We don't know how to use the machine, can you help us?

A: 1, We will send machine operation manual and CD together with machine;

2, If customer require, we will send technician to your factory teach you how to use it and maintain it;

3, You can send technician or workers to our factory, we will teach then how to use and maintain the machine.

5, Q: We are worry about the machine quality?

A: Our machine warranty is 3 years. Before ship the machine, we will test it about 7-10 days, when you received it,

you can use it directly, no need test it again.