.jpg)

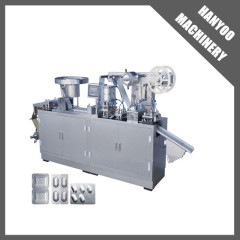

DPP-250E

| Min. Order: | 1 set |

|---|---|

| Payment Terms: | T/T OR L/C |

| Supply Ability: | 10sets per month |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Zhoushan, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

Product Detail

| Model No.: | DPP-250E |

|---|---|

| Means of Transport: | BY SEA/AIR |

| Specification: | 3540×720×1570mm |

| Certificate: | ISO |

| Export Area: | WORLDWIDE |

| Production Capacity: | 10sets per month |

| Packing: | WOODEN PACKAGE |

| Delivery Date: | 30 DAYS |

Product Description

1. MACHINE PROCEDURE:

■ This blister packing machine Forming film of reel support with automatic unwinding system.

■ Plate heating system. Lift-off on machine stop.

■ Compressed air forming station.

■ Filling device (Automatic or manual).

■ Coverfoil of reel support with automatic unwinding system.

■ Guide rails.

■ Sealing station.

■ Cooling station.

■ Punching station.

■ Waste winding unit.

2. ADVANTAGE OF THE PLATE SEALING DEVICE

■ Sufficient process time.

■ Constant and relatively low sealing temperature over the full sealing plaren.

■ Low energy cost.

■ Flexibility to seal a range of lid materials.

■ Proportional heat control with only +/- 5°C variation.

■ Uniform pressure distribution over the full platen surface.

■ Heat transfer to product is avoided.

■ Absorption of sealing load within the station.

■ Separation of indexing and sealing functions.

3. TECHNICAL DATA

|

Item

|

Data

|

|

|

Blanking frequency

|

20-50 times/min

|

|

|

Sheet's quantity of one blanking

|

3-4 sheets

|

|

|

Capacity

|

60~400 sheets/min

|

|

|

Adjustable scope of feed travel

|

10-160 mm

|

|

|

Max. Forming area and depth

|

250mm×160mm×25mm

|

|

|

Capacity of air compressor

|

≥0.36

|

|

|

Power supply

|

380V 500Hz 5.5KW

|

|

|

Wrapper specification

|

PVC for medicine

|

250mm×(0.15-0.5)mm

|

|

PTP aluminum foil

|

250mm×(0.02-0.035)mm

|

|

|

Overall dimension (L×W×H)

|

4300mm×1030mm×1640mm

|

|

|

Weight

|

2200Kg

|

|

|

Apply to

|

Packaging of capsule, tablet, chocolate, candy, food and electronic parts.

|

|

.jpg)