Double Belt Cooler for resin and other chemicals

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB,CIF |

| Payment Terms: | T/T |

| Place of Origin: | Shanghai |

Company Profile

| Location: | Shanghai, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

Product Detail

| Model No.: | JTDB |

|---|---|

| Means of Transport: | Ocean |

| Product Type: | Others |

| Machine Type: | Others |

| Delivery Date: | 60-90 days |

Product Description

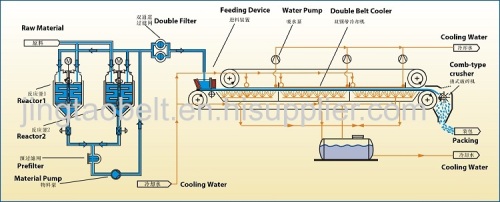

1. Process overview

Melt material flows through heat tracing pipe into trough in the front of double belt cooler and then overflows continuously and evenly onto surface between two steel belts.

The melt material loses heat to cooling water through the excellent heat conductive stainless steel belts and change into solid sheet during moving.

The solid sheet flakes off automatically at the end of steel belt. After break in crusher in the rear of double belt cooler, finish product is gathered to packing process.

Machine surface areas adjacent to moving parts are equipped with shields. Built-in interlock switch and emergency brake system ensure operation safety.

Cooling water won't contact with melt material in the double belt cooler. The uncontaminated cooling water can be recycled or discharged without pollution to the environment.

2. The capacity of double belt cooler is up to 10MT per hour subjecting to the coolability of chemicals

| Model | Capacity (kg/h) | Power (KW) | Water Flow (m3/h) |

| JTDF-1.5-12.5 | 1500-2500 | 10.2 | 45 |

| JTDF-1.5-17.5 | 2500-3500 | 13.6 | 65 |

| JTDF-1.5-22.5 | 3500-4500 | 18.3 | 85 |

| JTDF-1.5-25.0 | 4500-5500 | 24 | 95 |

| JTDF-1.5-27.5 | 5500-6500 | 24 | 105 |