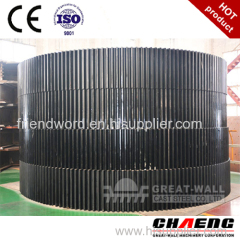

Ball Mill Girth Gear

| Min. Order: | 10 Set/Sets |

|---|---|

| Trade Term: | FOB,CIF,EXW |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 100 Setss/month |

| Place of Origin: | Henan |

Company Profile

| Location: | Luoyang, Henan, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

Product Detail

| Means of Transport: | Ocean |

|---|---|

| Production Capacity: | 100 Setss/month |

| Packing: | Ordinary packing |

| Delivery Date: | 30 WORK DAYS |

Product Description

We can offer OEM Service for Gear Steel Castings, and those steel castings can be produced in the following conditions:

· Heat treatment: Normalized, Normalized and Tempered, Quenched and Tempered

· Machining: Rough machined, Semi-finished machined, Finished machined

· Non-Destructive Testing: Magnetic Particle Testing, Ultrasonic Testing, Penetrant Testing

· Material: Carbon Steel, Alloy Steel, meet ASTM, BS, DIN, NF, JIS, ISO standard

· Individual Weight: 500KG – 140MT

Application:

· Mining

· Metallurgy

· Power Generation

· Cement Plant

· Port Machinery

We can also manufacture Bevel Gears, Helical Gear, Cylindrical Gear etc. Welcome your custom drawing.

Specification | Machining Scope |

Size | OD Max 16m |

One piece of Gear:OD Max 13m | |

Assemble Gear:According to drawings | |

Hobbing Modulds | 10-16 |

Milling Modulus | Up to 120 |

Spiral Grade | 1-15 |

Accuracy Grade | Milling: 6 grade |

Hobbing:8 grade | |

Material | Alloy steel:42CrMo4,34CrNiMo6 etc. |

Carbon steel:C45E, 1030 | |

Carburizing steel | |

Quenched and tempered steel | |

Heart treatment | Quenching&Tempering, Surface Quenching |

Teeth Profile | Spur, Helical, Herringbone, Crown, Spiral, Worm and shaft |

Girth gears are extensively used in most of the mills and kiln drive system. These gears are one of the highest cost components in the entire drive assembly. The girth gears have a very big diameter and high precision finish. The girth gears have a high efficiency and its overall life depends upon the proper lubrication and alignment.