Sterile Eye Drop Filling and Capping Machine

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB,CFR,CIF,DAT,FAS,DDP,DAP,CIP,CPT,FCA |

| Payment Terms: | Paypal, L/C, D/P, D/A, T/T, WU, Money Gram |

| Supply Ability: | 100 sets |

| Place of Origin: | Shanghai |

Company Profile

| Location: | Shanghai, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company, Service |

Product Detail

| Model No.: | R-VF/E |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| application: | eye drop |

| filling size: | 1-30ml |

| filling speed: | 30-100 bottles/min |

| control system: | PLC |

| dosing system: | piston pump |

| filling accurancy: | 0.8% |

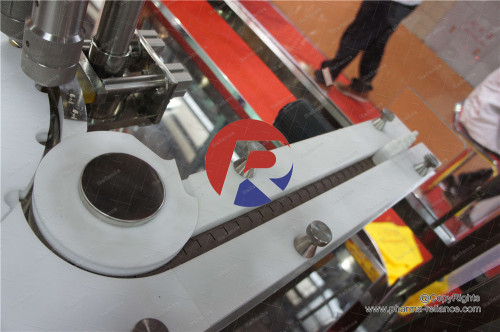

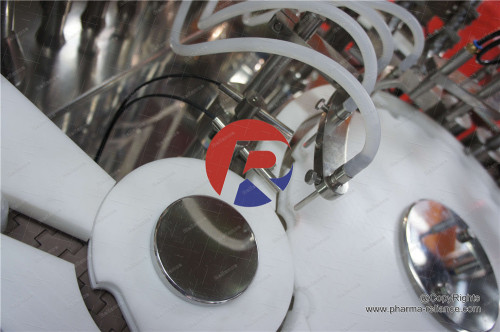

| function: | fill-insert-cap close |

| relative machine: | washing labeling machine |

| working condition: | sterile GMP |

| Production Capacity: | 100 sets |

| Packing: | wooden case |

| Delivery Date: | 60 days |

Product Description

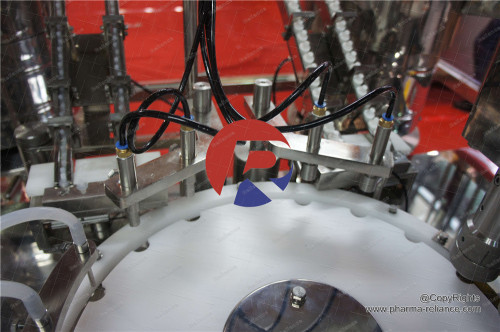

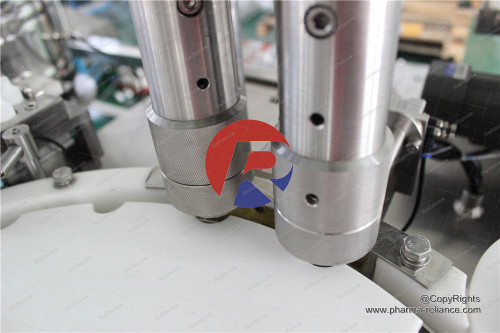

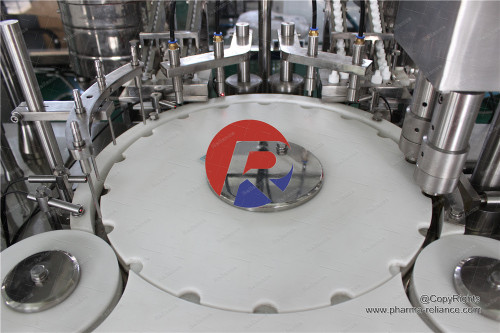

R-VF/E Monoblock Filler Plugger Capper machine this new system can be offered as a 3 function monobloc filling, tip/stopper placement, as well as cap/over-capping . The drive system and can be design with Servo or mechanical controls due to user's request. The large, full color touch screen allows the operator to adjust the servo controls for the diving nozzles as well as the pump fill rates. The machine has an ergonomic design offering a balcony frame for ease of inspection, maintenance, and quick size changeover.

Specifications | Model VF/E | |

Speed | >25 Bottles per Minute (Lower) | >50 Bottles per Minute (Higher) |

Changeover Time | 15 - 30 Minutes Typical | 15 - 30 Minutes Typical |

Drive Options | Servo or Mechanical | Servo or Mechanical |

System Controls | Touch Screen | Touch Screen |

Product Types | Liquids | Liquids |

Bottle Range | Round & Oval Shape & Square | |

Filling Range | 1-10ml,5ml-30ml,10ml-60ml, 60-120ml,100-250ml,250-500ml | 1-10ml,5ml-30ml,10ml-60ml, 60-120ml,100-250ml,250-500ml |

Dosing Pump | 1. Stainless Steel Pump (piston)+ Step ( Servo) Motor Drive 2. Peristaltic pump + Step ( Servo) Motor Drive 3. Ceramic pump+ Step ( Servo) Motor Drive | |

Dimensions | 2400mm L x 1500 mm W x 1750 mm H | |

Net Weight | 600kg to 750kg | |

Options | 1. Integrated Nitrogen Purge System 2. Explosion-Proof Motor 3. Standalone Electrical Cabinet 4. Positive Shut Off Nozzles 5. Tips & Caps On Inspection | |

.jpg)