Semi-regenerative Reforming f g

| Payment Terms: | L/C, T/T |

|---|---|

| Supply Ability: | 50 sets per month |

| Place of Origin: | Tianjin |

Company Profile

| Location: | Tianjin, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

Product Detail

| Production Capacity: | 50 sets per month |

|---|---|

| Packing: | 1 Set/wooden case |

| Delivery Date: | 30 |

Product Description

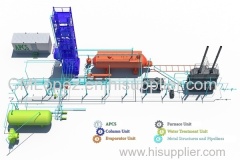

Semi-regenerative Reforming (SRR): With the help of heating, hydrotreating and catalyst, semi-regenerative reforming is a process which is used to convert petroleum refinery naphtha distilled from crude oil (typically having low octane ratings) into high-octane liquid products called reformates, which are premium blending stocks for high-octane gasoline. Compared with other regenerative reforming types, semi-regenerative reforming has advantages includes low investment, low operating fee…etc. Semi regenerative reforming can also be applied in various production scales.

Application of SRR:

1. Widely used in petrochemical industry.

2. In the hydrogenation, heating, high pressure conditions for light gasoline fractions or naphtha can be processed to be re-gasoline.

3. High-octane petrol is produced by using SRR.

4. Large amount of aromatics will also be produced.

Advantages of SRR:

1. PCC's SRR can save catalyst and other materials to the maximum extent

2. PCC's SRR is environmental friendly

3. By-product hydrogen is an important source of hydrogen for petroleum refinery hydrogenation units