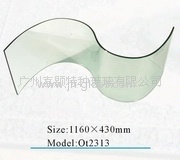

Tempered Laminated Curved Glass for building

| Trade Term: | FOB,CFR,DAT,DDP,CIP |

|---|---|

| Payment Terms: | Paypal, L/C, D/P, D/A, T/T, WU |

| Place of Origin: | Guangdong |

Company Profile

| Location: | Shenzhen, Guangdong, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

Product Detail

| Model No.: | DY-T001 |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Brand Name: | DYSG |

| Specification: | any |

| Bending Strength: | 4-5 times as annealed glass |

| Compressive Strength: | 95Mpa |

| Thickness: | 4-25mm |

| Transmittance: | 90% |

| Size: | max.3.3*7m |

Product Description

TEMPERED SAFETY GLASS is made by heating flat glass to just below its softening temperature (650 °c) and suddenly chilling it with jets of cold air. It results in the outer skins under powerful compressive stress and the interior with severe tensile stress. In consequence, the impact applied to the glass will be overcome by the compressive stress on the surfaces to assure safety of use. It is ideal for areas with high wind loads and areas where human contacts are an important consideration.

FEATURES:

1. 5 times harder than ordinary float glass, stronger resistance to thermal breakage than annealed or heat strengthened glass.

2. Once breakage occurs, the glass disintegrates into small cubical fragments, which are relatively harmless to human body.

3. It withstands abrupt temperature change of 220 Centigrade.

4. Sizes are produced as per customer request. Once tempered, it can not be cut down.

FEATURES:

1. 5 times harder than ordinary float glass, stronger resistance to thermal breakage than annealed or heat strengthened glass.

2. Once breakage occurs, the glass disintegrates into small cubical fragments, which are relatively harmless to human body.

3. It withstands abrupt temperature change of 220 Centigrade.

4. Sizes are produced as per customer request. Once tempered, it can not be cut down.