Big equipment auto lubrication system

| Min. Order: | 1 Set/Sets |

|---|---|

| Payment Terms: | L/C, T/T |

| Place of Origin: | Henan |

Company Profile

| Location: | Zhengzhou, Henan, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

Product Detail

| Model No.: | ALP3000 |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Packing: | wooden case |

| Delivery Date: | 20 days |

Product Description

Description

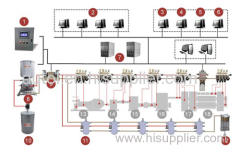

Centralized lubricaion system / Automatic greasing system for big equipment such as concrete equipment, harbor equipment, steel mill and sugar mill etc

Lubrication solution for heavy-duty equipment- take sugar mill equipment for example.

1.Automatic switchover of system

Switch the pump at low liquid level and add the grease automatically. The grease supply time and pause interval can be set according to the requirement. The system can interlock with the host equipment

2.Intelligent fault diagnosis

The system can diagnose the faults of each distributor. With the warning function for low liquid level, the system can indicate the fault type (blockage, through, leakage, getting stuck, broken) The fault database accumulated for several years can be used for reference.

3.Remote monitoring

Suit and satisfy the need of the modern factory's automatic production. Truly inflect the grease supply state of each lube point, making the equipment management personnel know fairly well. Remote setting and adjustment of the grease supply parameter of each lube point can meet the current need of the equipment lubrication.