large diameter pipes cnc Pipe threading lathe for oil country

| Min. Order: | 1 Piece/Pieces |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | Paypal, L/C, D/P, D/A, T/T, WU, Money Gram |

| Place of Origin: | Henan |

Company Profile

| Location: | Anyang, Henan, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company, Service |

Product Detail

| Model No.: | QK1212 |

|---|---|

| Means of Transport: | Ocean, Land |

| Raw Material: | Pipe |

| Power: | Cnc |

| Machine Type: | Others |

| Automation: | Automatic |

| Extra Services: | Machining |

| Material / Metal Processed: | Stainless Steel |

| Certification: | ISO 9001:2000 |

| Brand Name: | XINHENG |

| color: | blue |

| waranty: | 12 months |

| port: | Shanghai |

| packing: | wooden box |

| External Dia. of pipes: | 120mm |

| Swing over bed: | 800mm |

| Spindle bore: | 130mm |

| Max.length of turning: | 550-2800mm |

| Max.length of workpiece: | 750-3000mm |

| Taper hole of spindle: | metric 140 |

| Packing: | wooden box |

| Delivery Date: | 60 days |

Product Description

QK SERIES CNC PIPE THREADING LATHE (OIL COUNTRY LATHE):

The oil country lathe is mainly developed for the pipe thread turning in the oilfield and is suitable for turning of various pipe threads. The lathe belongs to a universal CNC pipe threading lathe of a semi-closed-loop control system and also can be used as a common CNC lathe, and is suitable for machining complicated shapes shaft, sleeve, disk parts. Such as turning, cylindrical surface, conical surface, arc surface, face, grooving, chamfering, thread and so on.

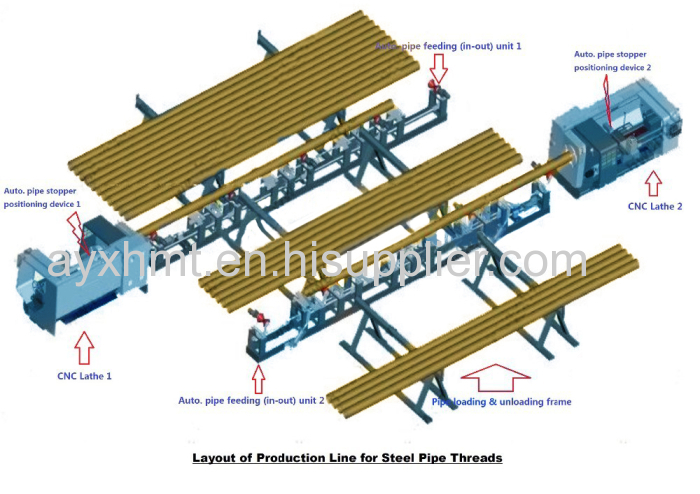

THE LAYOUT OF THE CNC PIPE THREADING LATHES:

TECHNICAL PARAMETERS:

| ITEM | UNIT | QK1212 | QK1219 | QKP1219 | QKP1223 | QKA1226/35 | QKA1246 | |

| CAPACITIES | External Dia. of pipes | mm | 120 | 190 | 190 | 230 | 260/340 | 460 |

| Swing over bed | mm | 800 | 800 | 1000/1100 | 1250 | |||

| Swing over carriage | mm | 450 | 480 | 630/730 | 900 | |||

| Max.length of workpiece | mm | 750-3000 | 1000~6000 | 1500~5000 | 2800 | |||

| Max.length of turning | mm | 550-2800 | 800-5800 | 1300~4800 | 2600 | |||

| Span of guideway | mm | 550 | 600 | 755 | 1100 | |||

| SPINDLE | Spindle nose | C15 | A2-15 | A2-20 | A2-28 | |||

| Taper hole of spindle | metric 140 | metric 213 | metric 213 | 1:20 | 1:20 | metric 140 | ||

| Spindle bore | mm | 130 | 200 | 200 | 240 | 275/355 | 465 | |

| Top taper of spindle | Morse 6 | |||||||

| Range of spindle speed | r/min | 20~1000 | 20~600 | 20~600 | 400/320 | 2~200 | ||

| Chuck | mm | 3-JAW 400 | 3-JAW 500/4-JAW 630 | 630/800 | 1000 | |||

| FEED | Min. feed of X/Z-axis | mm | 0.001/0.001 | |||||

| Rapid of X/Z-axis | m/min | 3/6 | 4/5 | |||||

| Max. travel of X | mm | 390 | 420 | 570/540 | 850 | |||

| TOOL POST&TAILSTOCK | Turret type | V4 240 | V4 300 | V4 380 | ||||

| Section of tool shank | mm | 40X40 | 50x50 | |||||

| Indexing repeatability | mm | 0.008 | ||||||

| Max.cutting force | N | 19600 | 29400 | 39200 | ||||

| Dia. /of tailstock | mm | 100/250 | 160/300 | 260/300 | ||||

| Taper hole of tailstock | Morse5 | Morse6 | metric80 | |||||

| OTHERS | Main power | kw | 22 | 30 | 15 | 18.5 | 28 | |

| Accuracy | IT6~IT7 | |||||||

| Roughness | RA1.6 | |||||||

| Length | mm | 2912~5177 | 3605~8485 | 4800-8300 | 6300 | |||

| Width | mm | 1800 | 2219/2330 | 2520 | 2720 | |||

| Hight | mm | 1850 | 1830/2100 | 2120 | 2320 | |||

| CNC system | Fanac/Siemens/Gsk | |||||||

FEATURES:

(1) The lathe body is integral casting structure.

(2) Strong rigidity headstock which can adapt to heavy processing.

(3) CNC system uses FANUC 0i Mate-TD (also according to customers' requirements match other systems)

(4) The spindle bore is 200mm, it is easy and enough for customer to feed pipes through the spindle bore, it can not only machining the surface for the bearing, but also can machining the thread or screw.

(5) We can customize the automatic feeding device according to different workpiece, the production will be competitive.

APPLICATION:

All kinds of drill pipe & drill collar, oil pipes and so on.

STANDARD CONFIGURATION OF THE CNC PIPE THREADING LATHES:

1. CNC System: FANUC Series 0i-mate-TD/0i-TD

2. X, Z motor with Fanuc feed servo motor 12Nm, 22Nm

3. Vertical 4-station electric turret 240X240/ 300×300/ 380×380

4. Guide rail width: 550mm/ 600mm/ 755mm

5. Spindle manual 3 files, hydraulic automatic 6 files, a total of 16 speed

6. Spindle bore 130mm/ 200mm/ 240mm

7. Double standard three-jaw self-centering chuck 380mm

8. The main hydraulic components use the Shanghai Electrical and Mechanical Services.

9. Semi-protection.

About Us

Anyang Xin heng Machine Tool Co. Ltd., is a large professional manufacturer of lathe, cnc lathe, pipe thread lathe, sphere turning lathe, cnc machine center etc. Our company has more than 30000sqm workshop and office building, and 60 year experience in machine tool production. Our products have been exported more than 50 countries . Welcome to visit our factory.