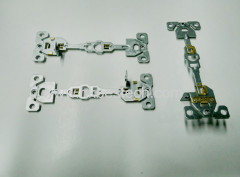

Through the improvement of mold design during stamping, add welding or tapping process in mold and fiber sensor to detect missing welding, thus achieved the integration of stamping, welding/tapping and inspection. The lifetime of each tooling is 5,000,000 times, and speed could be more than 70 times/min. It greatly increased capacity, reduced labor and process cost, and miantain more stable quality to compare with traditional manual welding.

Type : Forming in mold through feeding silver wire, contacts or profile tape, double side welding in one step also be available.

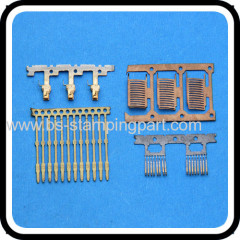

Material : Terminal/Spring: Copper, Brass, Phosphor copper, copper nickel, beryllium copper, white copper, Nickel, Aluminium, Iron, stainless steel, Monel,Clad metal ect.

Contacts: Ag, AgNi, AgCu, AgCuNi, AgCdO, AgSnO2, AgSnO2In2O3

Application Scope : Mainly used in Thermostat, Protector, Switch socket, Controller, and other middle or low voltage applances, and so on.

Capacity : 25,000,000pcs/month with more than 20 sets of equipments.