Professional EDM machining turning parts

| Min. Order: | 1 Piece/Pieces |

|---|---|

| Place of Origin: | Guangdong |

Company Profile

| Location: | Dongguan, Guangdong, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

Product Detail

| Model No.: | customization |

|---|---|

| Packing: | Foreign logistics (DHL, FEDEX, UPS, TNT) |

| Delivery Date: | 7 to 10 production days |

Product Description

Professional EDM machining turning parts

yizemould921108

Product name:turning partsProduct

size: customization

Material:Japan(SKD11.SKD61.SKH51.S45C)

USA(AISA.D2.H13.P20.M2)

Germany(DIN.2379.2363.2344.2347)

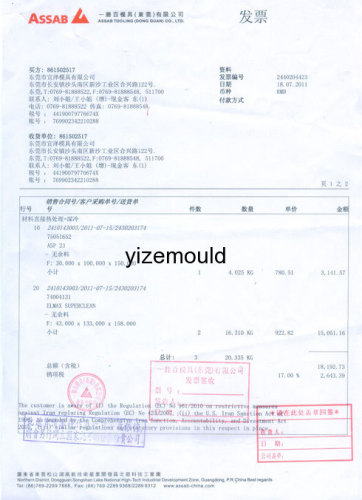

ASSAB(Rigor.Stavax.Impax.Elmax.ASP23)

Hardness:58-60 HRC

Grinding precision:0.001mm

Electric discharge processing precision:0.002mm

Packaging Details:Depends on customers' requirements

Delivery Detail:7~10 days

Add:Yize EDM department is equipped with twelve EDM machines including one set of Sodick EDM machine and four sets of Mitsubishi EDM machines. EDM precision within 0.003mm, EDM angle clearance within R0.015,EDM surface roughness within Ra0.2 are the technical precision available.

Compared with similar products, our advantages :

· We will keep tracing of every process in the manufacturing from the begining to the end.

· Every parts quality checked & cleaned before packing.

· Before parts delivery, clients could send one QC or point the third party to check the quality.

· After the delivery, we will keep tracing of the mould parts quality and we will try our best to help the clients when the problems happen.

Business steps

1.Sample/Drawing We need your detail require clearly.

↓

2.Negotiation Material,price,delivery time,payment term ,etc.

↓

3.Place order According your own design or choose our design.

↓

4.Mould design We will communicate&exchange the opinion with you during making drawing.

↓

5.Tooling mould After customer approve the mould design will start making mould.

↓

6.Mould process Provide photos for customer show them tooling process.

↓

7.Sample confirm Send you sample for confoirm it ,if not satisfied by customer.we modify mould .

↓

8.Delivery mould Delivery mould after customer approve sample and arrange shipment

The following processes are used:

1.CNC milling

2.EDM spark

3.Wire cut

4.EDM

5.Grinding

6.Drilling

7.Heat treatment

Authoritative attestation