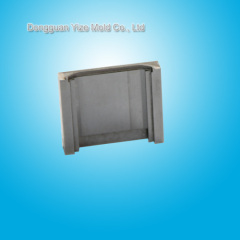

Super Quality Precision Stamping Mould Components

| Min. Order: | 1 Piece/Pieces |

|---|---|

| Place of Origin: | Guangdong |

Company Profile

| Location: | Dongguan, Guangdong, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

Product Detail

| Model No.: | customization |

|---|---|

| Brand Name: | YIZE MOULD |

| Packing: | Foreign logistics (DHL, FEDEX, UPS, TNT) |

| Delivery Date: | 7 to 10 production days |

Product Description

Super Quality Precision Stamping Mould Components

yizemould921108

Product Information

| Product name | precision stamping mould components |

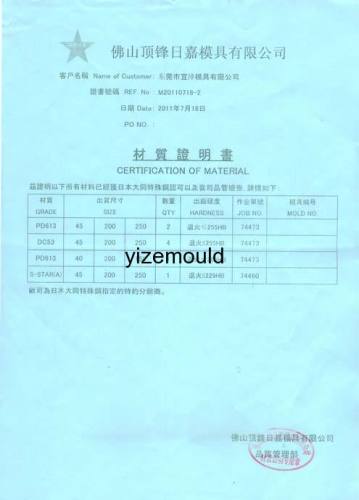

| Material | imported material:SKD11,SKH9,SKH51,SKH55,high-speed steel,special material can customize |

| Grinding precision | 0.001mm |

| Surface roughness for EDM | Ra 0.04 |

| EDM precision | 0.002mm |

| Grinding angle clearness | 0.002mm |

| MOQ | 1 PC |

Production Information

| Product accuracy | diamension tolerance ±0.001mm ,axiality within 0.002mm,roundness withing 0.0015mm,surfacae roughness wthin Ra 0.025,straightness within 0.002 |

| Technique standard | according to national standars GM,JIS,DIN,AISI,ect. and other national standard |

| Technique advantage | grinding parts with precision less than 0.002,precise EDM parts with precision less than 0.005 |

| Production equipment | all machinery used from import ,with EDM 15 sets,grinder 15 sets,,wire-cutting 3 sets,CNC 2 sets,milling machine 1 set |

| Our service | grinding process,grinding surface process,electro-discharge(wire EDM),CNC EDM,mirror EDM,CNC processing,precision mold parts process |

Business steps

1.Sample/Drawing We need your detail require clearly.

↓

2.Negotiation Material,price,delivery time,payment term ,etc.

↓

3.Place order According your own design or choose our design.

↓

4.Mould design We will communicate&exchange the opinion with you during making drawing.

↓

5.Tooling mould After customer approve the mould design will start making mould.

↓

6.Mould process Provide photos for customer show them tooling process.

↓

7.Sample confirm Send you sample for confoirm it ,if not satisfied by customer.we modify mould .

↓

8.Delivery mould Delivery mould after customer approve sample and arrange shipment

Compared with similar products, our advantages

1.16 steps of strict process in the elaborate production to make

perfect quality of mould components

2.Depending on advanced technology, mould lifespan can be multiplied.

3.Armed up with advanced equipment from Japan and an excellent

production team.

4.Rapid delivery(7~10 days)

5.Personal attention to details

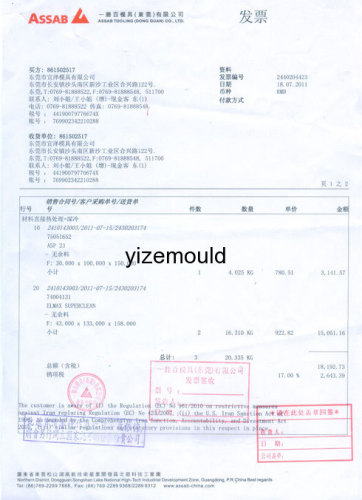

Authoritative attestation

About YIZE:

Dongguan YIZE MOULD Co.,LTD is a manufacturer specializing in precision mould components, precision plastic mould components, metal stamping mold components, connector mould components, non-standard round parts, carbide components. Products are used in many fields such as precision stamping mould, plastic mould, auto mould, pharmaceutical mould, computer connector mould and other factory automatic components. It has accumulated rich and professional experience in mould components manufacturing, technology, marketing and service, winning recognition and support from customer evaluation both at home and abroad.

Welcome to figure offer, the price is for reference only, we have a professional considerate service to you.