Tubular Coffee Maker Heating Element with Temperature Control

| Min. Order: | 1 Piece/Pieces |

|---|---|

| Trade Term: | FOB,CFR,CIF |

| Payment Terms: | Paypal, T/T, WU |

| Supply Ability: | 300000 Piece/Pieces per Month |

| Place of Origin: | Henan |

Company Profile

| Location: | Xinxiang, Henan, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

Product Detail

| Model No.: | JD30 2200w Diameter 10 E |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Certificates: | ROHS, CQC |

| Power: | 2200W |

| Thermal Efficiency: | ≥97% |

| Service Life: | >10,.000hours |

| Power Density: | ≤40W/CM2 |

| Temp Ramp: | up to 150℃/S |

| Dimension: | 60mm*161mm |

| Feature: | coffee maker heating element |

| Item Name: | electric heating element with temperature control |

| Other name: | tubular heating element |

| Production Capacity: | 300000 Piece/Pieces per Month |

| Packing: | Carton Box |

| Delivery Date: | 7-15 days |

Product Description

Tubular Coffee Maker Heating Element with Temperature Control

Instant Water Flow Continuous Heating

Descriptiom

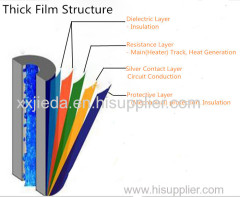

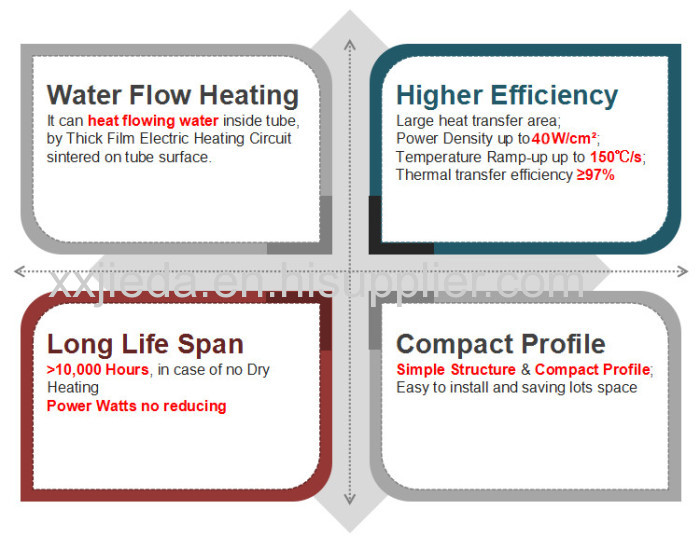

As a new type Tubular Coffee Maker Heating Element with Temperature Control, Thick Film Water Heating Element is larger heating area (Tubular Structure), higher power density (40w/cm2), faster temperature ramp up (150℃/S), longer life span (>10,000hours) and better thermal transfer (≥97%).

Tubular Coffee Maker Heating Element with Temperature Control 'S high power density make the temperature ramp up quickly, thermal should be taken away fast. So that we design it in tubular structure, which allow water flow inside tube. The electric heating circuit is made on surface's insulation layers, covered by another insulation layer.

Electric and water flow are insulated.

With its simple and small profile, it can be easily installed in home appliances electric instant water geyser or water dispenser.

Available water inlet and outlet port is in φ16mm, φ10mm, G1/2.

Available Power/Voltage: 2200W/220V, 3000W/220V

1500W/110V, 1700W/110V

It connects with wire leads by spot-weld to silver conductor on the surface.

Due to its high power density up to 60w/cm2, the thermal should be taked away quickly. So that we design this tubular thick film heating element, to let water flowing inside tube and take away the heat quickly.

Our Services

For applications where space is limited, this simple profile heating element offers high thermal power density and fast response times to heat up or cool down (due to low thermal mass).

Thick Film Heating Elements are widely applied in flowing water instant heating, such as electric water dispenser, water purifier, water geyser, Instant Water Kettle, instant coffee maker, electric faucet, instant shower heater, etc.

Specification

| Dimension | 20m*110mm | Heat Density | >60W/cm² |

| Ramp-Up Rate | 150℃/s | Thermal Efficiency | ≥97% |

| Heating Power | 2000W | Service Life | >10,000 hours |

| Rated Voltage | 220v | Certificate | CQC, RoHS |

| Dielectric Strength | 1,500V/5mA/60s | Power Deviation | -10% - +5% |

| Leakage Current | ≤0.25mA | Insulation Resistance | ≥200MΩ |

| Type | PA66+ glass fibre, temperature resistance≥250℃

| Application | to replace iron immersion electric water heating element |

| Shield Thermistor | PTC | Grounding Type | Spot-Weld |

| Water Inlet&Outlet | 20 | Heating Tube Dimention | Φ20mm*110mm |

Certification/Patent

Some clients have successfully applied UL/CE certificates for their finished products.

Related Products

Available Thick Film Heating Tube Element diameter are 18mm, 20mm, 30mm, 35mm, 40mm and 50mm

Power watts are 2.2kw, 3kw, 3.5kw, 3.8kw, 4kw, 5.5kw and 6kw

Mainly applied in Water Flow Instant Heating. Due to its long life time and higher thermal transfer, it's ideal to replace traditional immersion water heating elements.

Applications

The most compact instant type heating element is the ideal heating element for novel and fashionable home appliances such as Water Dispenser, Electric Water Faucet, Water Purifier, Coffee Maker, Milk Machine, etc.

Some of our Thick Film Electric Heating Tubes are individual customer solutions which are designed to match our customers' individual and specific requirements. During the development and application stages we work closely together with our customers in a partnership based on trust and mutual confidence.

About Us

Jieda locates in Xinxiang's Hi-Tech Development Park, which is 650km away from Qingdao. Jieda was founded in 2010, is a high-tech manufacturer that specializes in design, research, produce and sales rare-earth metal thick film electric heating tubes/elements.

What is Jieda advanced in?

1. More than 5 years experiences in thick film electric heating tubes.

2. Fully mastery of thick film tube surface screen printing and sintering.

3. Main Process Flow in 10000+ Grade Air Purification Workshop.

4. First manufacturer to mass produce Thick Film Electric Heating Tube/Element in China

5. Available various Solutions for fluid heating, especially for Instant Water Heating Home Appliances, House Floor Heating and Industrial water flow heating.

6. Monthly production capacity is up to 300,000 pcs.

What is Thick Film Heating Tube/Element advanced in?

1. The tubular structure makes it possible to instant heat water flow inside tube, by the Electric Heating Circuit printed and sintered on the tube surface.

2. It can work more than 10,000 hours, in case of no DRY HEATING.

3. The thermal transfer rate up to 97%.

4. Power Density is up to 60w/cm²

5. Temperature Ramp-Up Rate 150℃/S.

6. Boiling water(95℃) is available in 3 seconds around.

7. Simple & compact profile brings more possibility in new products research and design.

Those thick film heating tubes/elements are widely applied in Instant Water Boiling, Instant Water Heater, Water Dispensers, Coffee Makers, Instant Electric Heating Faucets, Steam Generator, Air-Flow Heater, Floor Heating, Industrial Water Flow Heating, etc.

It can successfully replace the Traditional Electric Heating Tubes/Elements, change their structures and performance completely, which can reduce energy consumption, increase energy utilization and save space.

OEM & ODM Service

Heating Power, Voltage, Stainless Steel Tube Dimension, Raw Materials and other special requirements can be customized.

Packaging & Delivery

------ Packed in Carton Box, placed on Wooden Pallet.

------ By Sea, FOB Tianjin Port, 40HQ, 40 GP, 20 GP, LCL, or Mix with Others Factory, no Space Waste, Save Freight Cost!

------ By Air, FedEx, DHL, TNT, UPS...

------ Support Global Dilivery!

FAQ

| FAQ |

Q: What's Thick Film Heating Element? A: -Thick Film Heater is a new technical art which is use screen printing technology and new thick film material. It is printed with isolation dielectric, heating element and glass prevent on a substrate that is made by stainless steel, amd through drying firing process with 800°C. Thick Film Heater has become a new type of heater. |

Q: What's the advantages of Jieda Thick Film Heating Element? to heat continuous water flow without water tank. 60W/CM² POWER DENSITY UP TO 150℃/S TEMPERATURE RANP UP |

Q: What's the lifespan of Thick Film Heating Tube / Thick Film Heating Element? |

Q: What's the inlet and outlet diameter? Thick Film Heating Element : Available with Ø10mm, Ø16mm and G1/2 OD20.9mm |

Q: Can I DIY it for personal use by myself? A: Our Products are mainly used as heating spare parts for water heaters in mass production, not recommended for Personal DIY. |

Q: Can the Thick Film be applied to Copper Pipe or Aluminum Pipe? A: It can not be applied on Copper pipe, but can work on Aluminum pipe. |

Q: How to get the suitable model for our application? and other special requirements, to recommend the suitable Thick Film Heating Elements |

Q: What's the operation attentions? 2. Please install it vertically, make sure water flow direction from bottom to top, to prevent DRY HEATING in partial area of heating tube. 3. Set the minimum flow rate according to tubes' power watts, ensure smooth flowing of water, to prevent vaporizing and dry heating 4. Make sure reliablility grounding. |