400 x 600/ 750x1060 Jaw Crusher

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB,CFR,CIF,DAT,FAS,DDP,DAP,CIP,CPT,FCA,EXW |

| Payment Terms: | Paypal, L/C, D/P, D/A, T/T, WU, Money Gram |

| Supply Ability: | 100 sets/ month |

| Place of Origin: | Henan |

Company Profile

| Location: | Zhengzhou, Henan, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

Product Detail

| Model No.: | PE250*400, PE250*1000, PE400*600 |

|---|---|

| Means of Transport: | Ocean, Land |

| Application: | Ore |

| Type: | Crusher |

| Brand Name: | XKJ |

| Name: | Jaw Crusher |

| Application: | crushing machine with accessories is applied in ore and stone |

| Motor Type: | AC Motor |

| Power(W): | 2.2-200KW |

| Capacity(t/h): | 10-800 TPH |

| Dimension(L*W*H): | 1108*1090*1392, 2790*2670*1380, 1663*1732*1586, 1930*2062*2246(mm)etc. |

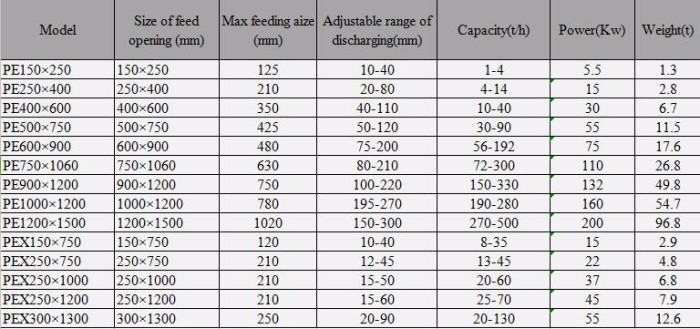

| Weight: | 2.8t, 6.7t, 11.5t, 17.6t, 26.8t, 49.8t, 54.7t, 96t |

| Certification: | ISO9001, CE |

| Input Size: | 80-1200mm |

| Output Size: | 20-350mm |

| Production Capacity: | 100 sets/ month |

| Packing: | Standard container, the spare parts is packed in wooden cases. |

| Delivery Date: | within 20 days |

Product Description

Application

Jaw crusher is easy to install, operate and maintain.It is widely used in fields of mining, metallurgy, construction, smelting, hydropower and chemical industries etc., mainly for the medium-grained crush of veriety of ores, stones, and minerals, etc. It is the corollary equipment of sand/stone making plant and ore beneficiation plant. Also it can produce road cornerstone stones and construction stone aggregate.

Advantage and Feature

a. High efficiency with uniform particle size.

b. Simple structure is easy to operate, reduce the operation cost.

c. Crushing chamber is deep and has no dead space, which helps improve the feeding capacity and productivity.

d. Adjustment device of gasket type discharging end is reliable and convenient to use.

e. The discharging end has wide adjusting range which can increase the flexibility of our equipment.

f. Lubrication system is safe and reliable.

g. Over loading protection.

h. Accessories are convenient to replace, and little maintenance is needed.

i. Long service life.

Working Principle

The working principle of jaw crusher is very simple. The whole crushing process rely on the relative motion of the two jaw plates. One of the jaw plates is fixed and stay still, the other moves against it by a cam or pitman mechanism.

During this movement, the materials between the two plates would be crushed progressively into small particles: while the plates move against each other, the materials would be crushed, and while plates move apart from each other, the broken materials which are smaller enough would drop through the discharging opening. The movement of the jaw can be quite small, since complete crushing is not performed in one stroke. Due to the simple structure, jaw crusher is easy to maintain and repair. These features promote its popularity to a great extant.

Specification