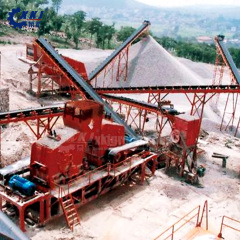

Stone Crushing Machinery Equipment

| Min. Order: | 1 Set/Sets |

|---|---|

| Payment Terms: | Paypal, L/C, D/P, D/A, T/T, WU, Money Gram |

| Supply Ability: | 20SETS/MONTH |

| Place of Origin: | Henan |

Company Profile

| Location: | Zhengzhou, Henan, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

Product Detail

| Means of Transport: | Ocean |

|---|---|

| Application: | Others |

| Type: | Crusher |

| Brand Name: | XKJ |

| Name: | Stone Production Line |

| Capacity(t/h): | 15-800TPH |

| After-sales Service Provided: | Engineers available to service machinery overseas |

| Max feeding Size: | 200-700mm |

| Applications: | Mining, metallurgy, construction, highway, railroad, etc. |

| Color: | as your demand |

| Structure: | Reasonable |

| Maintenance: | Easy operation |

| Operation: | High automatic degree |

| Market: | Africa,Europe,Asia,etc |

| Production Capacity: | 20SETS/MONTH |

| Packing: | Standard export containers,motors and small parts are packed in wooden cases. |

| Delivery Date: | within 30 days after receiving your deposit |

Product Description

Stone Production Line Introduction

stone crushing machinery equipment production line includes vibrating feeder, jaw crusher, impact crusher, vibratingscreen, belt conveyor and centrally electric controlling system, etc.The designed capacity of stone crushing machinery equipment production line is from 50t/h to 500t/h. To meet customers specific requirement, we can also add other equipments such as cone crusher, dust catcher on the production line.

Stone Production Line Process

Large stone materials from the storage hopper are evenly and continuously fed into jaw crusher through vibrating feeder for primary crushing; the crushed materials are transported to cone crusher or impact crusher for fine crushing through belt conveyor; then the materials are transported to vibrating screen to be separated into different sizes. The end products with desired sizes will be transported to the final product pile and those with big sizes will return to the cone crusher or impact crusher for re-crushing. This forms closed and continuously automatic cycles. The plant can be equipped with dust removing facilities to protect environment according to customers' requests.

Details about primary crushing, medium and fine crushing

1.Crushing: feed particle size is 300~900mm, the grain size is 100~550mm;

2.Pieces: feed particle size is 100~350mm, the grain size is 20~100mm;

3.Fine: feed particle size is 50~100mm, the grain size is 5~15mm.

↓↓↓

Click " Send " Now !