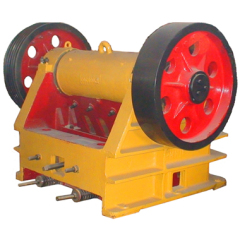

Portable Stone Jaw Crusher

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB,CFR,CIF,DAT,FAS,DDP,DAP,CIP,CPT,FCA,EXW |

| Payment Terms: | Paypal, L/C, D/P, D/A, T/T, WU, Money Gram |

| Supply Ability: | 100 sets/ month |

| Place of Origin: | Henan |

Company Profile

| Location: | Zhengzhou, Henan, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

Product Detail

| Model No.: | PE250*400, PE250*1000, PE400*600, PE500*750, etc. |

|---|---|

| Means of Transport: | Ocean, Land |

| Application: | Ore |

| Type: | Crusher |

| Brand Name: | XKJ |

| Name: | Jaw Crusher |

| Application: | crushing machine with accessories is applied in ore and stone |

| Motor Type: | AC Motor |

| Power(W): | 2.2-200KW |

| Capacity(t/h): | 10-800 TPH |

| Dimension(L*W*H): | 1108*1090*1392, 2790*2670*1380, 1663*1732*1586, 1930*2062*2246(mm)etc. |

| Weight: | 2.8t, 6.7t, 11.5t, 17.6t, 26.8t, 49.8t, 54.7t, 96t |

| Certification: | ISO9001, CE |

| Input Size: | 80-1200mm |

| Output Size: | 20-350mm |

| Production Capacity: | 100 sets/ month |

| Packing: | Standard container, the spare parts is packed in wooden cases. |

| Delivery Date: | within 20 days |

Product Description

Portable Stone Jaw Crusher

Application

Jaw crusher is easy to install, operate and maintain.It is widely used in fields of mining, metallurgy, construction, smelting, hydropower and chemical industries etc., mainly for the medium-grained crush of veriety of ores, stones, and minerals, etc. It is the corollary equipment of sand/stone making plant and ore beneficiation plant. Also it can produce road cornerstone stones and construction stone aggregate.

Advantage and Feature

a. High efficiency with uniform particle size.

b. Simple structure is easy to operate, reduce the operation cost.

c. Crushing chamber is deep and has no dead space, which helps improve the feeding capacity and productivity.

d. Adjustment device of gasket type discharging end is reliable and convenient to use.

e. The discharging end has wide adjusting range which can increase the flexibility of our equipment.

f. Lubrication system is safe and reliable.

g. Over loading protection.

h. Accessories are convenient to replace, and little maintenance is needed.

i. Long service life.

Working Principle

The working principle of jaw crusher is very simple. The whole crushing process rely on the relative motion of the two jaw plates. One of the jaw plates is fixed and stay still, the other moves against it by a cam or pitman mechanism.

During this movement, the materials between the two plates would be crushed progressively into small particles: while the plates move against each other, the materials would be crushed, and while plates move apart from each other, the broken materials which are smaller enough would drop through the discharging opening. The movement of the jaw can be quite small, since complete crushing is not performed in one stroke. Due to the simple structure, jaw crusher is easy to maintain and repair. These features promote its popularity to a great extant.

Specification

Packaging & Shipping

Mini Small Lab Jaw Crusher Machine Price List with CE Certificate is exported to more than 50countries and districts all over the world. We promise to ship about 30 working days after payment. The payment can be L/C, T/T and other negotiation.

Our Services

24 hours online customer service, detailed and professional solution.

Skilled engineers, scene investigation, free customized program solution.

The purchase contract has a certain reputation guarantee, provide you the perfect product to your hands.

After-sales service support, Expert technical training and operating instructions, site installation and commissioning, adhere to test equipment and visit our customers regularly.

We offer all kinds of models, high-quality crushing and screening equipment parts.

FAQ

We are manufacturer of 21 years experiences, not dealer.

We exported to more than 50 countries and districts all over the world.

We have a professional team to ensure your best pre-sale service, sale service and after-sale service.

Why choose us

Please fill in your need products and your message and do not forget mail and/or phone if you like to be contacted.

Please notice : we are the professional machine manufacturer in China,not dealer.

I need to ask you some details for sending you the more suitable quotation,

1.what is the raw material do you want to process?

2.what is the capacity per hour do you need?

3.what is the raw material input size?

4.what is the output size of your product?

I hope you can tell me these details, we can design the production line for you according to your requirments. If you need design service, pelase let us know your raw material size,finished products size and capacity.Our engineer will give you the best solution. thanks.

Contact us if you need more details.