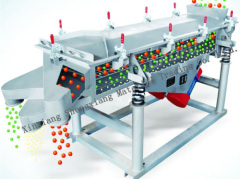

Stainless steel linear vibrating screen

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB,CFR,CIF |

| Payment Terms: | L/C, D/P, D/A, T/T |

| Supply Ability: | 150 sets per Year |

| Place of Origin: | Henan |

Company Profile

| Location: | Xinxiang, Henan, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

Product Detail

| Model No.: | WZS |

|---|---|

| Means of Transport: | Ocean |

| Type: | Others |

| Application: | Ore |

| Brand Name: | Winner |

| Motor Power: | 1.5-3kw |

| Double amplitude: | 4-8mm |

| Vibration times: | 960r/min |

| Processing capacity: | 0.1-20t/h |

| Sieves number: | 1-6 |

| Vibration direction angle: | 45-60 degree |

| Production Capacity: | 150 sets per Year |

| Packing: | Product standard container export, reach to the requirements sea transportation |

| Delivery Date: | Shipped in 30 days after payment |

Product Description

WZS series stainless steel linear vibrating screen

Introduction Overview:

The WZS series stainless steel linear vibrating screen produced by our company has the advantages of high reliability, low consumption, low noise, long service life, high stability, high screening efficiency and so on. Often cooperate with other mechanical equipment, such as conveyor, hoist, crusher, etc., to complete the whole assembly line automation.

Application:

Mainly used for abrasive abrasive materials, chemicals, plastics, medicine, resin powder, ceramic raw materials, metallurgy, building materials, food, fertilizer and other industries in the dry powder, fine granular or fine powder materials screening.

Advantages:

1.The screening machine is suitable for high capacity of rough sub operations.

2.Materials on the sieve surface has a long stroke, large amount of treatment.

3.Materials screening and parallel transmission can be carried out simultaneously.

4.It can adjust the screen surface inclination to balance the accuracy of screen production.

Technical parameter table:

Model | Screen surface dimensions(mm) | Sieves number | Processing capacity(t/h) | Vibration times(r/min) | Double amplitude(mm) | Motor Power(kw) | Vibration direction angle(°) |

3WZS1020 | 1000×2000 | 3 | 0.10-2 | 960 | 5-7 | 2×0.75 | 45-60 |

4WZS1020 | 4 | 0.07-15 | 960 | 4-8 | 2×0.75 | 45-60 | |

5WZS1020 | 5 | 0.07-15 | 960 | 4-8 | 2×1.5 | 45-60 | |

6WZS1020 | 6 | 0.07-15 | 960 | 4-8 | 2×1.5 | 45-60 | |

WZS830 | 800×3000 | 1 | 0.1-20 | 960 | 6-8 | 2×0.75 | 45-60 |

2WZS830 | 2 | 0.1-20 | 960 | 6-8 | 2×0.75 | 45-60 | |

3WZS830 | 3 | 0.1-20 | 960 | 6-8 | 2×1.5 | 45-60 | |

WZS1030 | 1000×3000 | 1 | 0.1-20 | 960 | 6-8 | 2×0.75 | 45-60 |

2WZS1030 | 2 | 0.1-20 | 960 | 6-8 | 2×1.5 | 45-60 | |

3WZS1030 | 3 | 0.1-20 | 960 | 6-8 | 2×1.5 | 45-60 |