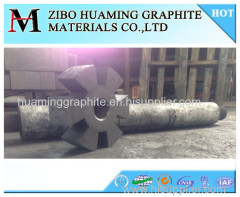

specifications of graphite rotor and shaft

1 Used for degassing in molten aluminum

2 Total Anti-oxidation treatment to enhance lifespan

3 Size and Shape: Customize production

During metal and alloy smelting, hydrogen produced by chemical action with steam diffuse in molten metal and alloy, which will cause inner structural defect to products. In order to avoid such defect, most foundry factories apply dissolved gas floating method to purify molten metal and alloy. i.e. inert gases such as nitrogen, argon is injected into the liquid, and hydrogen will be brought to molten metal and alloy surface with spread and rise of inert gas.

Rotor and shaft set is necessary to inject inert gas and stir for degassing regarding both intermittent and continuous online degassing methods. Because of properties of heat-resistance, anti-oxidation, high strength and non- infiltration, graphite becomes the optimal choice for material of rotor and shaft, which is named graphite rotor/impeller and shaft set.

characteristics of graphite rotor

1.high density and high hardness

2.high mechanical strength

3.good oxidation resistance

4.high temperature resistance

5.low porosity

6,anti-abrasion

7,antioxidation

8.anti-scour

9.corrosion resistance

Features/benefits: durable, cost effective

Performance characteristics:

* Machined with high quality graphite billet.

*Treated with three times special oxidization retardant process to prolong their operating life.

*According to the using conditions of the user, the use of special anti-oxidation process,