Multiple effect plate evaporator

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | T/T |

| Supply Ability: | 30 sets per year |

| Place of Origin: | Shandong |

Company Profile

| Location: | Jinan, Shandong, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

Product Detail

| Model No.: | MUL03 |

|---|---|

| Means of Transport: | Ocean |

| Brand Name: | KJH |

| stable operation: | energy saving |

| Production Capacity: | 30 sets per year |

| Packing: | Shipped in container |

| Delivery Date: | 100 days |

Product Description

Material: Stainless304,316L,2205, Titanium and Nickel

Application field:

Food Concentration(Dairy, Starch, Sugar, Beverage and Fruit Juice),Pharmaceuticals concentration, Black liquor concentration, Solid and liquid separation of wastewater.

Service provided:

Final inspection before delivery; installation and debugging on

customer's side; operator training ,24 hours online service and abroad engineer service.

Lead time: 100 days

Payment term: T/T

Advantages

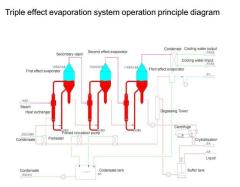

1.Energy saving: The secondary vapor produced by evaporation can be used as heat steam at next effect

2.High automatic: Applying PLC automatic control system, automatic control feed time and discharge time, CIP automatic cleaning, automatic generation of operation data, automatic alarm

3.High manufacture standard, high quality parts ,stable to run.

Energy consumption per ton of evaporated water:

Single effect: about 1.2 tons steam

Double effect: about 0.6-0.7 tons steam

Triple effect: about 0.37-0.46 tons steam

Quadruple effect: about 0.3-0.35 tons steam

Quintuple effect: about 0.24-0.3 tons steam

Multiple effect evaporator is developed from the most primitive evaporation tank to single effect, double effect, triple effect, quadruple effect or more effect, the purpose of which is to gradually reduce energy consumption.

The principle of multiple effect evaporator is to utilize the secondary vapor generated by the previous effect to heat the next effect to achieve the goal of energy saving.