China leading Automatic Wheelset Press Hydraulic Wheel Press

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 60sets per year |

| Place of Origin: | Hubei |

Company Profile

| Location: | Ezhou, Hubei, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

Product Detail

| Model No.: | HQ01 |

|---|---|

| Means of Transport: | Ocean |

| Brand: | Heqiang Machinery |

| Certificates: | ISO9001, ISO14001, OHSAS18001 |

| Origin: | Hubei, China |

| Product application: | Railway depot, vehicle factory/depot |

| Usage: | Mount / dismount wheelset components |

| Working pressure: | 2000kN ~ 5000kN |

| Power source: | Hydraulic |

| Power supply: | 380V/50HZ, AC 3 phase |

| Painting color: | Depends on client's request |

| After-sale service: | Engineer Available to Service Machinery Oversea |

| Production Capacity: | 60sets per year |

| Packing: | Machine frame in nude pack and other components packed in strong wooden cases. |

| Delivery Date: | 3~6 months after received deposit |

Product Description

NEW CONDITION DOUBLE CYLINDER AUTOMATIC WHEELSET PRESS, HYDRAULIC WHEEL PRESS FOR RAILWAY VEHICLE MANUFACTURE/MAINTENANCE

1. Product overview:

Heqiang Machinery Hydraulic Wheel Presses are used for mounting / dismounting and back pressure testing wheel-set components such as wheels, brake discs, gear, gearbox, etc. on to / off of axles for all railway rolling stocks. They are available with the following features:

Pressing force of 2,000kN up to 5,000kN;

Single or double end cylinders;

Perfect centering of the wheelset during the mounting and dismounting process;

Loading and unloading operations by means of a manually operated or fully automatic trolley;

Automatic component positioning by means of a measuring device mechanically or laser operated;

Mounting and dismounting of wheelset components with a single positioning on the wheel press;

Standard roll-in or pass-through design;

Automatic recording of mounting curve, radial and axial run-out and back pressure test of each mounted component.

2. Main Features:

Gantry frame structure, Dual-end cylinders, special anti-upsetting centres and movable resistant column, with delicated trolley for wheelset loading and unloading. It's suitable for assembly line.

Fully Automatic control, CNC operating system, easy to learn, achieving the convenience and visualization of operation;

High accurate measuring device, ensure that both wheel inner distance and wheel position difference can reach the relevant requirements;

Multiple function of System software, including wheel calibration function, function of automatic record, intelligent judgement, print, save and query to wheel pressing curve of pressure vs displacement

Unique hydraulic servo system, adjustable pressing speed, can realize the mounting, dismounting and back-pressure test requirements of various types of wheelset;

Center hole positioning, pressing without turning the axle, shorten the working time and improve the process efficiency.

3. Main Technical Parameters:

| Working pressure | 2000KN ~ 5000KN |

| RAM cylinder qty | 2PCS |

| RAM stroke | 0~600mm, 0~700mm, 0~900mm |

| Fast forward speed | 0~25mm/s |

| Press mounting speed | 0~5mm/s |

| Return speed | 0~45mm/s |

| Center supporting weight | 10000kgs |

| Electrical Trolley qty | 1 set |

| Trolley supporting weight | ≤ 10000kgs |

| System pressure | 0~31.5MPa |

| Main power supply | 380V, 50Hz |

| Inner distance control accuracy | < 0.5mm |

| Wheel position difference control accuracy | < 0.2mm |

| RAM positioning accuracy | < 0.04mm |

| Error of Measuring accuracy | ≤ 0.01mm |

| Concentricity of Main cylinders' centerline | ≤ 0.08mm |

| Max wheelset weight | ≤ 10000kgs |

| Axle length | 1700~2700mm |

| Wheel diameter | Φ740 ~ 1250mm |

| Wheel seat diameter | Φ150 ~ 270mm |

| Wheel hub diameter | Φ180 ~ 400mm |

(Above parameters are indicative and can be modified as per customer's actual requirements.)

4. Application examples

CRRC Datong Electric Locomotive Co.,Ltd;

CRRC DALIAN CO.,LTD.

CRRC SIFANG CO.,LTD.;

CRRC QINGDAO SIFANG CO.,LTD.;

CRRC ZIYANG CO.,LTD.

CRRC LUOYANG CO.,LTD.

CRRC TAIYUAN CO.,LTD.;

KENYA RAILWAYS;

MYANMA RAILWAYS;

etc.

5. Installation and Commissioning

The Seller is responsible for the installation and commissioning of the machine. If the damage and product quality problem caused during installation and commissioning results in the machine fail to meet the technical agreement and product processing requirements, the machine can be returned or replaced and all the economic losses caused will be borne by the Seller.

6. Technical training

Technical training will be taken place at the user site during installation and commissioning of the press. The manufacturer will be responsible for the technical training of the user's operators, product technicians, CNC programming personnel and Mechanical/electrical maintenance personnel, until they have the abilities of operation, maintenance and programming.

The manufacturer/seller shall provide the training materials for the trainers. The effect of the second technical training shall be signed by the buyer and taken as one main content of the final acceptance.

7. Warranty and After-sale service

The warranty period of the wheel press will be 12 (twelve) months from the date of final acceptance qualified and signed by both parties. During the warranty, the manufacturer will be responsible to repair or replace the damage component caused due to the machine quality. The manufacturer will response within 24 hours after receive the fault notice from the Buyer.

At the end of the warranty, the Seller shall arrange to the user site to carry out a free fully adjustment and maintenance.

After the warranty period, the Seller will provide a wide range of technical support.

The after-sale service includes all aspects, such as mechanical, hydraulic, electronic control, operation, training, software upgrade, etc. The manufacturer will keep in stock for the basic spare parts.

8. Inquiry or Questions

If you have interests or questions, please feel free to contact with us by email or visit our company website.

COMPANY PROFILE:

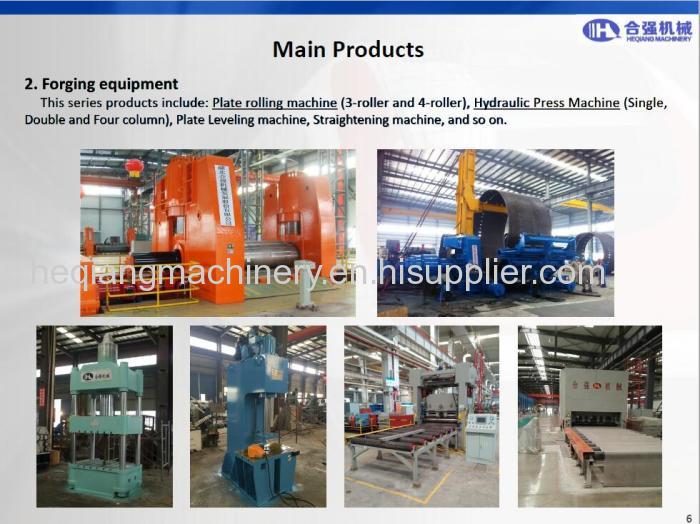

Hubei Heqiang Machinery Development Limited by Share Ltd. is located in Ezhou of Hubei province. Since its establishment in December of 2000, the company is mainly engaging in the development, manufacture and sales of Rail transit manufacture/maintenance equipment and forging equipment, and providing supporting service for related equipment. After more than 10 years' rapid development, Heqiang Machinery has already grown into the leading manufacturer of rail transit equipment and forging equipment in the market.

The company covers an area of 40,000 square meters, with more than 120 employees, including 40 professional technical personnel and medium/senior engineers. It has 2 subsidiary companies: Beijing Heqiang Delian Technology Co.,Ltd, Responsible for sales and services at north of China; Nanjing Hengqin Environmental Technology Co.,Ltd. in environmental equipment. The company now has more than 100sets equipment on metal processing, welding and testing, and has initially formed an unique device configuration and quality control system.

We have already established good business relationship with many customers, such as CRRC and China Railway Administration etc., also our machines are exported to foreign users, such as Kenya, Myanmar, Vietnam, Indonesia, Malaysia, Saudi Arabia, Iran, Thailand and etc. Till now, we have supplied more than 350sets of rail transit equipment and 600sets of forging equipment.