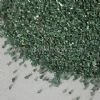

98% Black silicon carbide Grit

| Min. Order: | 1 Ton |

|---|---|

| Payment Terms: | L/C, T/T, WU |

| Supply Ability: | 5000 ton/month |

| Place of Origin: | Henan |

Company Profile

| Location: | Zhengzhou, Henan, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

Product Detail

| Model No.: | F24-F280 |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Brand Name: | Haixu |

| Material: | Black silicon carbide |

| Usage: | Sandblasting |

| Abrasive Grain Sizes: | F24-F280 |

| Hardness: | 9.2 |

| Standard: | JIS/ISO/GB/FEPA |

| Color: | black |

| Product name: | 98% Black silicon carbide Grit |

| Production Capacity: | 5000 ton/month |

| Packing: | 25kg PVC bag+1MT big bag |

| Delivery Date: | Shipped in 3 days after payment |

Product Description

Description:

Black Silicon carbide is an extremely hard carborundum, it is produced at high temperature in an electric resistance type furnace with quarts sand and petroleum.

Silicon Carbide is produced by a process involving the electrochemical reaction of silica(SiO2) – in the form of quartz mixed with Carbon(C) in the form of raw petroleum. The stoichiometric mixture is reacted in an electrical resistance furnace at a temperature up to 2500℃ to yield high quality crystals. The process is large furnace technology with a graphite electrode in the furnace center. The large crystals are then segregated, crushed, cleaned of magnetic impurities in high intensity magnetic separators and classified into narrow size fractions to suit the end use. Dedicated lines produce products for different applications.

Properties:

High hardness, retaining hardness and strength at high temperature.

High wear resistance.

Excellent thermal shock resistance with high thermal conductivity and low linear thermal expansion.

Good ability to withstand the strongest alkalis and acids.

· low density

· low thermal expansion, oxidation resistance

· excellent chemical resistance

· high thermal shock resistance

· high wear and hardness resistance

· high strength, high temperature resistance

· high temperature strength

Applications:

Coated abrasive tools such as polishing wheel, sanding paper, flap disc, fiber disc, etc.

Lapping and polishing,

Refractory, Furnace Burden, Casting, Ramming Compound, Refractory Bricks etc

Kiln furniture

Blasting, surface Treatment, Rust Removal

Grinding wheels, sandpaper etc

Raw material of Knife Grinder, Whetstone, oilstone, grinding stone, abrasive stones and so on

Wear resistance parts

TYPICAL CHEMICAL ANALYSIS | ||

SiC | ≥98% | |

SiO2 | ≤1% | |

H2O3 | ≤0.5% | |

Fe2O3 | ≤0.3% | |

F.C | ≤0.3% | |

Magnetic content | ≤0.02% | |

TYPICAL PHYSICAL PROPERTIES | ||

Hardness: | Mohs:9.2 | |

Melting Point: | dissociated at about 2300 °C | |

Maximum service temperature: | 1900℃ | |

Specific Gravity: | 3.2-3.45 g/cm3 | |

Bulk density(LPD): | 1.2-1.6 g/cm3 | |

Color: | Black | |

Particle shape: | Hexagonal | |

Modulus of Elasticity | 58-65x106 psi | |

Coefficient of Thermal Expansion | 3.9-4.5 x10-6/ ℃ | |

Themal Conductivity | 71-130 W/MK | |

AVAILABLE SIZES | ||

8# 10# 12# 14# 16# 20# 22# 24# 30# 36# 40# 46# 54# 60# 70# 80# 10# 12# 14# 16# 20# 22# 24# 30# 36# 40# 46# 54# 60# 70# 80# 90# 100# 120# 150# 180# 220# | ||