Cooking oil mill plant manufacturer edible oil production machine line

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB,CFR,CIF |

| Payment Terms: | Paypal, L/C, D/P, T/T, WU |

| Supply Ability: | according to the customer requirements |

| Place of Origin: | Henan |

Company Profile

| Location: | Zhengzhou, Henan, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Distributor/Wholesaler |

Product Detail

| Model No.: | cooking oil processing machine |

|---|---|

| Means of Transport: | Ocean |

| Brand Name: | Doing |

| Type: | cookig oil machine |

| Condition: | New |

| Customized: | Customized |

| Certification: | CE&ISO9001 |

| Origin: | Henan China (Mainland) |

| Usage: | Mainly used to refine edible oil |

| Production Capacity: | according to the customer requirements |

| Packing: | wooden case or according to the customer requirements |

| Delivery Date: | 50 days |

Product Description

Henan Doing Company, which is established in 2011, dealing principally oil pressing machinery and turn-key oil processing projects including designing, manufacturing, installing and debugging. We are experienced in building oilseed processing plant, oil milling plant, mechanical oil pressing line, solvent extraction plant and oil refining machine. View our website to find detailed information about cooking oil mill plant, oil seed processing equipment, oil extraction machine, oil filtering machine other related oil mill machinery. Want to start your oil business and build a customized, sophisticated oil pressing plant with low investment? Henan Doing machinery should be your best choice!

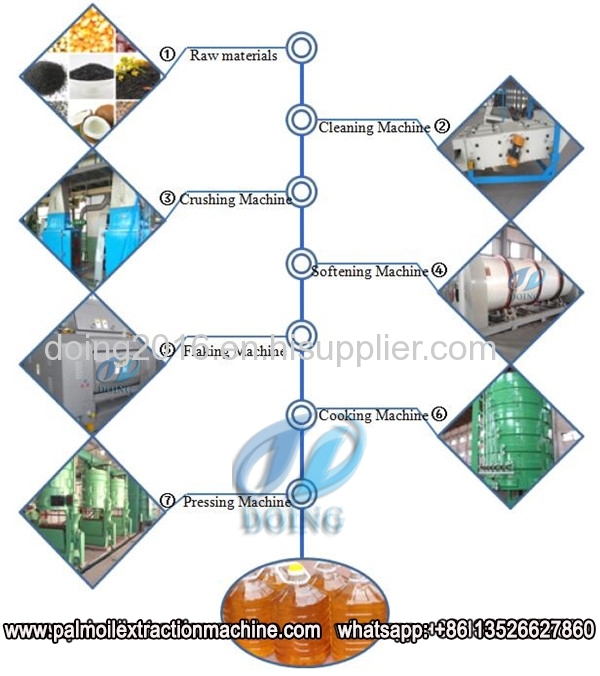

Edible oil mill plant comprises of the following different processes:

The oilseeds pretreatment and press section greatly affect the oil extraction efficiency and production cost. Before feeding into cooking oil expeller (oil press), the oilseeds must be cleaning to remove impurities, otherwise they may damage the expeller, increase maintenance costs and reduce the quality of final oil product.

oilseeds cleaning section;

oilseeds crushing section;

oilseeds flaking section;

oilseeds cooking section;

oilseeds pressing section;

oilseeds clarification section;

The following is the solvent extraction process flow chart of vegetable oil production machine:

Edible oil solvent extraction production line comprises of the following different processes:

Edible oil solvent extraction plant is used to extract cooking oil from pressed cake which is the second process of vegetable oil production. After the edible oil solvent extraction process, there is only less 1% oil content in meal.

Solvent extraction system;

D.T.D.C system;

Condenser system;

Recovery system;

The following is the refining process flow chart of vegetable oil production machine:

Our cooking oil refining machine can process various kinds of crude oil. Edible oil refining machine is another important machine of vegetable oil production .Edible oil refining is a step by step process. Our edible oil refining machine including a series of refining processes which are aim to remove phospholipids, FFA, pigment, gums, waxes, off-flavor and other impurities from crude edible oil.

Edible oil refining production line comprises of the following different processes:

Degumming Process

Degumming Process

Neutralizing Process(Deacidification process)

Bleaching Process

Deodorizing Process

Our company provide various types of edible oil production machine to customize different oil processing capacity. We ensure the best quality and best price. If there are any needs, please email us!