Outdoor Stranded Optical Fiber Cable for Network

| Min. Order: | 2000 Meter |

|---|---|

| Trade Term: | FOB,CIF,EXW |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 4 million core km |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Hangzhou, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

Product Detail

| Model No.: | GYTA53 |

|---|---|

| Means of Transport: | Ocean |

| Application: | Telecommunications |

| Type: | Optical Fiber |

| Brand Name: | DuMei |

| Number of Conductors: | 2-432 |

| Operating Temperature: | -40℃~+60℃ |

| Type: | Single-Mode Fiber |

| Connectors: | SC-SC |

| Material Shape: | Round Wire |

| Allowable lateral press: | >1000(N/100m) |

| Allow tensile strength: | 1000N<10000N |

| Transport packaging: | 3km/Wooden Drum |

| Sheath material: | PE |

| Country of origin: | China |

| Production Capacity: | 4 million core km |

| Packing: | usually 3km/wooden drum or according to your requirement |

| Delivery Date: | about 15 days without transport |

Product Description

GYTA53 Outdoor Stranded Optical Fiber Cable for Network

Cable Type:GYTA53

Loose Tube Fiber

Central Strength Member

SZ layer stranded fiber filling with special filling Compound

APL adheres tightly with PE Sheath

Corrugated PSP coheres tightly with PE Sheath.

Description

The fibers, 250μm, are positioned in a loose tube made of a high modulus plastic. The tubes are filled with a water-resistant filling compound. A steel wire, sometimes sheathed with polyethylene (PE) for cable with high fiber count, locates in the center of core as a metallic strength member. Tubes (and fillers) are stranded around the strength member into a compact and circular cable core. An Aluminum Polyethylene Laminate (APL) is applied around the cable core. which is filled with the filling compound to protect it from water ingress. Then the cable core is covered with a thin PE inner sheath. After the PSP is longitudinally applied over the inner sheath, the cable is completed with a PE outer sheath.

Application:

1,Long distance and local area network

2,Suitable for direct buried laying.

3,Operating Temperature:-40ºC-+60ºC

Cable Characteristic:

1,Low dispersion and attenuation

2,Proper design,precise control for fiber excess length and distinct stranding process render the cable excellent mechanical and environmental performance.

3,Compact fiber structure, especially using SZ layer stranded structure to keep the cable away from stress in bad environment.

4,Strength Member and water blocking filling compound is applied to keep the cable moisture proof and water proof.

5,PSP and APL double longitudinal wrapping structure,double PE sheath with strong crush resistance are applied to preventing rodent animal damage.

Product perameter

| Model Number | GYTA53 |

| Type | Optical Fiber |

| Number of Conductors | Multicore |

| Certification | TLC, ISO |

| OEM | Welcome to OEM |

| Jacket Material | PE |

| Outdoor Laying Mod | Directly buried |

| Application | 1,Duct/Aerial 2,Local area network system and Subscriber network system 3,Long distance communication system |

| Operating Temperature | -40 to 60 degree |

Technical parameters:

| Items | unit | Details | |

| Fiber counts | -- | Multicore | |

| Optical fiber | Type | -- | G.652,G.655 |

| PE sheath | -- | YES | |

| Tension (Long/Short Term) | N | 1000/3000 | |

| Crush (Long/Short Term) | N/100mm | 1000/3000 | |

| Min. Bending radius | Dynamic | 30times cable diameter | |

| Static | 15times cable diameter | ||

| Temperature range | Operation | -40°C to 60°C | |

| Application | Outdoor | ||

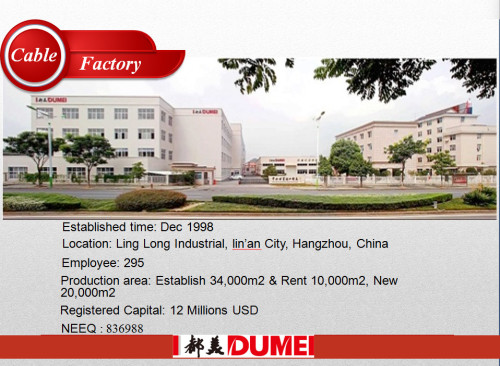

1, Cable Factory

2, Advanced Measurement Equipments

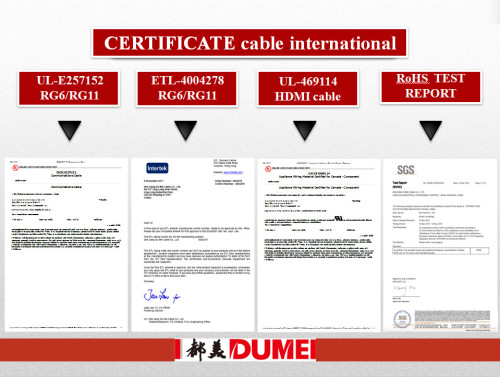

3, Certifications