Turning rolls with Halnn CBN Inserts

| Min. Order: | 10 Piece/Pieces |

|---|---|

| Payment Terms: | T/T |

| Supply Ability: | 200000 |

| Place of Origin: | Henan |

Company Profile

| Location: | Zhengzhou, Henan, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Service |

Product Detail

| Model No.: | BN-K1, BN-S20 |

|---|---|

| Means of Transport: | Ocean, Air |

| materials: | cbn insert |

| Application: | machining rolls |

| Production Capacity: | 200000 |

| Packing: | Carton |

| Delivery Date: | 8 days |

Product Description

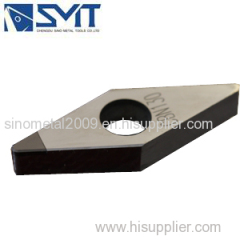

Turning rolls with Halnn CBN inserts BN-S20 and BN-K1

Turning mill roll commonly use Halnn superhard BN-K1 and BN-S20 grade CBN inserts, they are solid CBN insert, which not only can achieve large margin cutting, improve production efficiency, but also are helpful for the green manufacturing of the roll industry with dry cutting.

BN-K1 CBN inserts mainly is used for processing cast iron mill roll, the cast iron hardness is high, specially the large cast mill roll surface exist casting defects. Using Halnn superhard BN-K1 cbn insert not only can achieve large margin turning, and won't collapse when encountered sand, porosity and other hard spot, it will improve significantly production efficiency, the lifetime will be carbide inserts ten times, and ceramic inserts several times.

BN-S20 cbn inserts mainly is used for processing high hardness steel mill roll, the forged steel mill roll has better toughness, the uniformity of surface hardness and fatigue resistance than cast mill roll, so choosing BN-S20 cbn inserts with strong impact toughness, the processing advantage is evident. When processing Swedish forged cold roll with BN-S20 cbn inserts, the cutting depth is 4-7mm, the cutting speed is 90m/min, the process efficiency of BN-S20 is common CBN insert 2.5 times.