Komatsu PC100 excavator bucket teeth

| Min. Order: | 200 Piece/Pieces |

|---|---|

| Trade Term: | FOB,CIF |

| Payment Terms: | L/C, D/P, T/T |

| Supply Ability: | 500tons per month |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

Product Detail

| Model No.: | 20X-70-23161 |

|---|---|

| Means of Transport: | Ocean, Air |

| spare part for bucket: | forged product |

| Production Capacity: | 500tons per month |

| Packing: | plywood case |

| Delivery Date: | 10 days |

Product Description

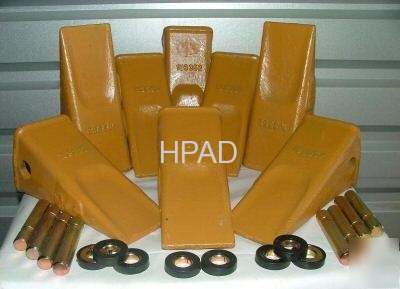

Komatsu PC100 bucket teeth 20X-70-23161

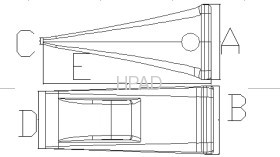

| PC100 | 20X-70-23161 | 2.2kg | A;80 B;77 C;6.5 D;61.5 E178 |

Basic Info.

· Application: Construction machinery, Ground Engaging Tools

· Better Surface: Better Surface

· Material: Alloy Steel

· Desc: bucket teeth

· Equipment type: EXCAVATOR

· Condition for bucket tooth: New

· Impact: above 20J

· HARDNESS: HRC48-52

· Model No.: 20X-70-23161

· Place of Origin: Zhejiang, China

· Min.Order: 200 Piece/Pieces

· Means of Transport: Land, Ocean, Air

Supply Capacity

· Production Capacity: 500tons per month

· Packing:wooden case

· Delivery Date: 10 days

Advantage:

1), Short delivery : 10 days for one full container;

2), Price: competitive price compare to casting teeth ;

3), Surface: No any casting defect.

4), Can be produced according to your drawing

5), Professional forging 20 years

Our trade & market:

Domestic Market

Southeast Asia

South America

Northern Europe

Middle East

Africa

Southern Europe

Eastern Asia

Western Europe

Eastern Europe

North America

Central America

The bucket teeth are forged, not casting. They are used for a wide range of excavators, for example Komatsu, Daewoo, Caterpillar, Volvo, Kobelco, Hyundai etc.

Forging is kind of method which uses forging machine to press the metal blank to make it produce plastic deformationand obtain a certain mechanical property, shape and size.

Forging can eliminate the defection of as-cast loose during metallurgy process and improve the microstructure.

The mechanical property of forging bucket teeth is generally better than that of the same material of casting bucket teeth, because forging craftsmanship can keep the intact metal streamline.

Our quality control department is equipped with the first-class testing and inspection facilities,such as spectorometer imported from Germany,Optical metallographic microscope,Hydraulic universal tensile strength machine,Low temperature impact testing instrument,Bush hardness tester and magnetic particle inspector.

With stable performance, excellent wear resistance and high performance-price ratio, our products will be your Ideal choice!