Hypertherm PowerMax 125 Consumables For Plasma Cutter Machine

| Min. Order: | 5 Piece/Pieces |

|---|---|

| Trade Term: | EXW |

| Payment Terms: | T/T, WU |

| Supply Ability: | 10,000pcs per month |

| Place of Origin: | Shanghai |

Company Profile

| Location: | Shanghai, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

Product Detail

| Model No.: | Nozzle 220975 |

|---|---|

| Power: | Cnc |

| Automation: | Automatic |

| Certification: | GS |

| Brand Name: | Plasma Consumables |

| Nozzle 220975: | Long life |

| Production Capacity: | 10,000pcs per month |

| Packing: | Manufacturer packing |

| Delivery Date: | Prompt goods |

Product Description

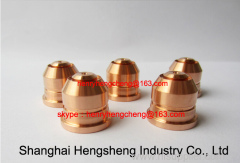

Plasma Consumables Nozzle 220975 For Hypertherm PowerMax125 Plasma Cutter Machine

We can offer you all plasma consumables for hyptertherm, Kjellberg, Esab, Koike, Komatsu, Thermadyne, such as: electrode, nozzle, shield, swirl ring, inner cap, retaining cap, water tube, torch body and so on.

In recent years, we have been sold in lots of countries and regions in Europe and Asia and gained good reputation widely with excellent quality . In order to meet customers' requirements and improve product quality, our company has already realized mechanical processing numerical control automatization production, and been committed to manufacturing products with best quality.

Machine | HEC NO. | Ref NO. | Description |

PowerMAX125 | H71997 | 220997 | Swirl Ring 45/65/125Amp |

H71159 | 420159 | Swirl Ring 45Amp FineCut | |

H01971 | 220971 | Electrode 45/65/85/105/125Amp | |

H11158 | 420158 | Nozzle 45Amp | |

H11169 | 420169 | Nozzle 65Amp | |

H11975 | 220975 | Nozzle 125Amp | |

H11151 | 420151 | Nozzle 45Amp FineCut | |

H11001 | 420001 | Nozzle 30-125A gouging | |

H41977 | 220977 | Retaining Cap 45/65/125Amp | |

H41156 | 420156 | Retaining Cap 45/65/125A mechanized, ohmic | |

H21168 | 420168 | Shield 45/65Amp mechanized | |

H21172 | 420172 | Shield 45/65A drag-cutting | |

H21976 | 220976 | Shield 125Amp mechanized | |

H21000 | 420000 | Shield 125A drag-cutting | |

H21152 | 420152 | Shield 45A FineCut | |

H21112 | 420112 | Shieldg 30-125A gouging |

Technical Support:

Plasma cutting machine matters needing attention

The selection of cutting parameters of CNC plasma cutting machine is very important for cutting quality, cutting speed and efficiency. The correct use of CNC plasma machine for high quality fast cutting, cutting process parameters must be deeply understood and mastered.

First, cutting current: it is the most important cutting process parameters, directly determines the cutting thickness and speed, that is, cutting ability. Effects: 1, cutting current increases, an increase in the energy of the arc, cutting ability, the cutting speed is increased; 2, cutting current increases, increasing the diameter of the arc arc variable rough makes incision width; 3, cutting current ambassador to the nozzle increases the heat load, the nozzle premature damage, cutting quality of the natural decline, can't even normal cut. So the cutting current and the corresponding nozzle should be chosen according to the thickness of the material before cutting.