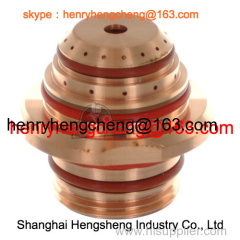

Plasma Cutting 120787 For Hypertherm HT4400 Plasma Cutter Accessories

| Min. Order: | 5 Piece/Pieces |

|---|---|

| Payment Terms: | T/T, WU |

| Supply Ability: | 10,000pcs per month |

| Place of Origin: | Shanghai |

Company Profile

| Location: | Shanghai, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

Product Detail

| Model No.: | Nozzle 120787 |

|---|---|

| Means of Transport: | Air |

| Production Capacity: | 10,000pcs per month |

| Packing: | Manufacturer packing |

| Delivery Date: | Prompt goods |

Product Description

Plasma Cutter Machine Nozzle 120787 For Hypertherm HT4400 Plasma Cutter Accessories

Shanghai HengSheng Welding & Cutting Technology Can supply various models of plasma Consumables electrode, nozzle, shield, swirl ring, inner cap, retaining cap, water tube, torch body, such as HT4400, HPR400XD, HPR260XD, HPR130XD, HPR260, HPR130, HSD130, HD3070, HD4070, HT2000, MAX200, POWERMAX1650, POWERMAX1250, POWERMAX65, POWERMAX85, POWERMAX45, POWERMAX30 and so on.

Plasma Consumables, plasma cutting accessories, plasma cutter parts, plasma cutting consumables, plasma cutter consumables, plasma cutting tips, plasma cutter tips, plasma cutter tips and electrodes, plasma cutting electrode, plasma machine torch, plasma cutting torch, plasma torch parts, Plasma cutter Swirl Ring, plasma cutter nozzle,plasma cutting nozzle

1. Can make as per customer's requirements. Almost Every Parts Have A Lot Of Stock.

2.The strict quality control. Our products processed are using CNC machines, we have fifteen sets of high-precision testing equipment and Eighty experienced skilled workers.

3. Welcome to contact us. You Can Send Us E-Mail, Skype, WhatSapp, Wechat or Call us.

4.Outer packing:standard export carton.

5.Have any questions, pls feel free to inform us.

Machine | HEC NO. | Ref NO. | Description |

HPR 130 HPR 260 HPR 130XD HPR 260XD HPR 400XD | H03192 | 220192 | Electrode,30Amp |

H03552 | 220552 | Electrode,50Amp | |

H03187 | 220187 | Electrode,80Amp | |

H03181 | 220181 | Electrode,130Amp | |

H03352 | 220352 | Electrode,200Amp | |

H03435 | 220435 | Electrode,260Amp | |

H03649 | 220649 | Electrode,130Amp Bevel | |

H03541 | 220541 | Electrode,260Amp Bevel | |

H03665 | 220665 | Electrode,130Amp(silver Plus) | |

H03666 | 220666 | Electrode,200Amp(silver Plus) | |

H03668 | 220668 | Electrode,260Amp(silver Plus) | |

H03629 | 220629 | Electrode,400Amp | |

H73180 | 220180 | Swirl Ring,30Amp | |

H73553 | 220553 | Swirl Ring,50Amp | |

H73353 | 220353 | Swirl Ring,200Amp | |

H73179 | 220179 | Swirl Ring,80/130/260Amp(Bevel) | |

H73436 | 220436 | Swirl Ring,260/260Amp(Bevel) | |

H73631 | 220631 | Swirl Ring,400/400Amp(Bevel) | |

H13193 | 220193 | Nozzle,30Amp | |

H13554 | 220554 | Nozzle,50Amp | |

H13188 | 220188 | Nozzle,80Amp | |

H13182 | 220182 | Nozzle,130Amp | |

H13354 | 220354 | Nozzle,200Amp | |

H13439 | 220439 | Nozzle,260Amp | |

H13646 | 220646 | Nozzle,130Amp(Bevel) | |

H13542 | 220542 | Nozzle,260Amp(Bevel) | |

H13632 | 220632 | Nozzle,400/400Amp(Bevel) | |

H33754 | 220754 | Retaining Cap 30/50Amp | |

H33176 | 220176 | Retaining Cap 80/130Amp | |

H33355 | 220355 | Retaining Cap 200Amp | |

H33433 | 220433 | Retaining Cap 260Amp | |

H33603 | 220603 | Retaining Cap (Bevel) 130/260Amp | |

H33756 | 220756 | Retaining Cap 80/130Amp | |

H33757 | 220757 | Retaining Cap 200Amp | |

H33760 | 220760 | Retaining Cap 260Amp | |

H33635 | 220635 | Retaining Cap 400/400Amp(Bevel) | |

H33740 | 220740 | Retaining Cap (Bevel) 130/260Amp | |

H23194 | 220194 | Shield,30Amp | |

H23555 | 220555 | Shield,50Amp | |

H23189 | 220189 | Shield,80Amp | |

H23183 | 220183 | Shield,130Amp | |

H23356 | 220356 | Shield,200Amp | |

H23440 | 220440 | Shield,260Amp | |

H23645 | 220645 | Shield,130Amp(Bevel) | |

H23545 | 220545 | Shield,260Amp(Bevel) | |

H23761 | 220761 | Shield,200Amp | |

H23764 | 220764 | Shield,260Amp | |

H23636 | 220636 | Shield,400/400Amp(Bevel) | |

H23742 | 220742 | Shield,130Amp(Bevel) | |

H23741 | 220741 | Shield,260Amp(Bevel) | |

H43173 | 220173 | Retaining Cap 30/50/80/130Amp | |

H43398 | 220398 | Retaining Cap 200/260/(Bevel)130/260Amp | |

H43747 | 220747 | Retaining Cap 30/50/80/130Amp | |

H43637 | 220637 | Retaining Cap 200/260/400Amp(Bevel) | |

H83818 | 128818 | HPR torch assembly | |

H83162 | 220162 | Quick-disconnect torch | |

H83163 | 220163 | Quick-disconnect recepticle | |

H83706 | 220706 | Quick-disconnect torch | |

H83705 | 220705 | Quick-disconnect recepticle | |

H93571 | 220571 | Water Tube with O-Ring | |

H93340 | 220340 | Water Tube with O-Ring(30/50/80/130/200/260Amp) | |

H93700 | 220700 | Bevel water tube(mild steel-130A) |

Technical Support:

Plasma cutting machine matters needing attention

The selection of cutting parameters of CNC plasma cutting machine is very important for cutting quality, cutting speed and efficiency. The correct use of CNC plasma machine for high quality fast cutting, cutting process parameters must be deeply understood and mastered.

1, arc voltage: generally considered the normal output voltage of the power supply is the cutting voltage. Plasma arc cutting machine usually has a high no-load voltage and operating voltage, in the use of high ionization energy such as nitrogen, hydrogen or air, the voltage required to stabilize the plasma arc will be higher. When the current is constant, the increase of the voltage means the increase of the arc enthalpy and the improvement of the cutting ability. If the enthalpy is increased, the jet diameter and the gas flow rate can be reduced, and the faster cutting speed and better cutting quality can be obtained.

2, working gas and the flow: gas including cutting gas and auxiliary gas, some of the equipment but also for gas arc, usually to according to the type of cutting material, thickness and cutting method to select the appropriate work gas. Cutting gas is not only to ensure the formation of plasma jet, but also to ensure the removal of the molten metal and oxide cut. A large gas flow will take more heat from the arc, making jet length becomes shorter, resulted in cutting capacity is decreased and arc instability; too small gas flow the plasma arc lost due to the straightness and the cutting depth shallow, but also easy to produce hang slag; so the gas flow must with cutting current and speed very good cooperation. Now the plasma arc cutting machine mostly rely on gas pressure to control the flow, because when the gun body pore size, control the gas pressure will control the flow. Gas pressure to cut a certain plate thickness is usually chosen according to the data provided by the equipment manufacturer. If there are other special applications, the gas pressure needs to be determined by the actual cutting test. The most commonly used working gases include argon, nitrogen, oxygen, air and H35, argon nitrogen gas mixture, etc..