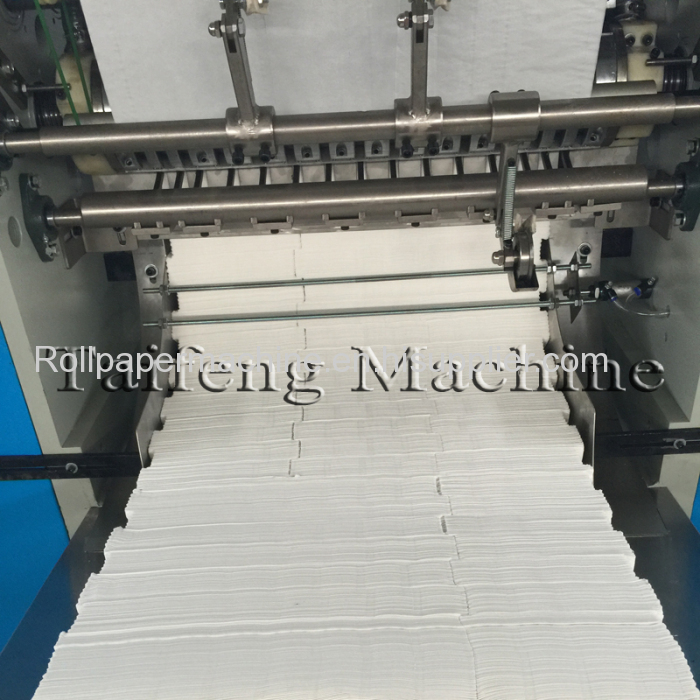

2017 New Automatic Paper Folding Machine Drawing Type Facial Tissue Paper Machine

12000.0 USD

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB,EXW |

| Payment Terms: | T/T, Cash |

| Supply Ability: | 30 sets/year |

| Place of Origin: | Fujian |

Company Profile

| Location: | Quanzhou, Fujian, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

Product Detail

| Model No.: | TF-FT-04 |

|---|---|

| Means of Transport: | Ocean |

| Product Type: | Facial Tissue |

| Certification: | CE |

| Processing Type: | Paper Folding Machine |

| Brand Name: | Taifeng |

| Color: | bule-white/designed by buyer |

| Product type: | facial tissue |

| Warranty: | 1 year |

| Accessories: | 5 Knife Blades For Free |

| Operate speed: | 1600pcs/min |

| Power(W): | 5.5KW |

| After-sales Service: | Engineers available to overseas service provided |

| Dimension(L*W*H): | 4.1x1.3x2.1m |

| Production Capacity: | 30 sets/year |

| Packing: | In seaworthy package |

| Delivery Date: | 50-60 working days |

Product Description

Function and Character:

Facial Tissue Box Making Machine Paper is conducted by spiral cutting by sections with convenient adjustment in cutting tool

Folding type: V type folding, paper in upper and lower position are jointed and folded with auto counting unit and output in stack, folding with vacuum adsorption. Box-Drawing Facial Tissue Machine,

Unwinding of jumbo roll is pushed a fed by the flat belt, equipped with stepless speed regulator to adjust tension of unwinding.

Slitting width can be adjustable while products are in trim.

It can be equipped with embossment unit as per client's requirement

Adopt PLC and frequency speed regulator control by Box-Drawing Face Tissue Machine

Main Technical Specifications:

Model(Lane) TF-2L Max raw Paper Roll Width 420mm Raw Paper Material 12-18g/m x 2layers Max Raw Paper roll Dia Standard φ1100mm Raw Paper Roll Core Dia 3' (76.2mm) Finished Products Opened Size (140,150,160-210) x (140-210) (mm) Finished Products Folded Size (70-105) x (140-210) (mm) Operate Speed (sheets/min) 1600 Finished Production Rate≥98% Mechanical Driving Driven by stepless frequency control system Program Controller PLC control, Touch Screen Edge Embossing Steel to Steel, Independent Adjustment Slitting Unit Full Cutting Lubricating System Key Parts Regularly Lubricating Automatically Counting System Alternate Stack by Stack Pneumatic System 3HP Air Compressor ,Mini Pressure 5kg/cm2 Pa Paper Layer 2-3Layer Raw Paper Roll Core Dia 3' (76.2mm) Finished Products Opened Size (140,150,160-210) x (140-210) (mm) Finished Products Folded Size (70-105) x (140-210) (mm) Operate Speed (sheets/min) 1600 Finished Production Rate≥98% Lubricating System Key Parts Regularly Lubricating Automatically Vacuum System 5.5kw Main Power 2.2kw Machine Size(m) 4.1x1.3x2.1 Weight(ton) 1.8T