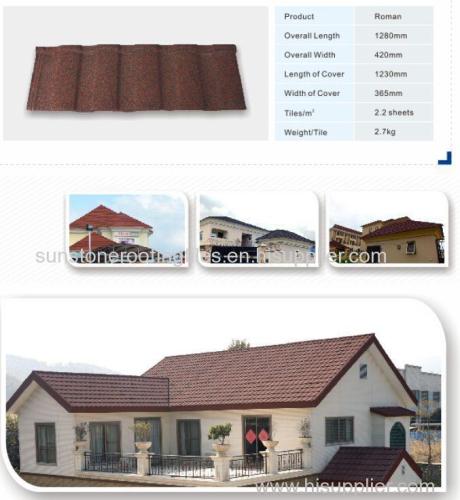

stone coated metal roof tiles / 2017 new stone coated steel roof tiles roof sheet

| Min. Order: | 100000 Piece/Pieces |

|---|---|

| Payment Terms: | Paypal, L/C, T/T, WU, Money Gram |

| Supply Ability: | 100000 pcs per month |

| Place of Origin: | Guangdong |

Company Profile

| Location: | Guangzhou, Guangdong, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

Product Detail

| Model No.: | roman |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Brand Name: | SUNSTONE ROOF |

| Material: | Aluminium Zinc Alloy |

| Waterproof: | 50 Years |

| Thickness: | 0.4mm |

| Item Name: | China best stone coated metal roof tiles |

| Treatment: | Ceramic Stone Coating |

| Size: | 1280*420mm |

| Color: | Chestnut, Sandal Brown, Originatal Red,coffee,green |

| Production Capacity: | 100000 pcs per month |

| Packing: | wooden pallet and protection foam |

| Delivery Date: | within 15 working days after deposited |

Product Description

Feature:

1. Durable: Stone coated metal roofing system has the advantages of heat-resisting, corrosion resisting and ageless.

2. Safe: The unique waterproof, windproof, the installation design, together with the advantages of natural stone and steel, Metal Roofing System can against of strong wind, heavy rain, and hail penetration.

3. Light-weight: Stone coated roof tile is only 1/6 of the weight of normal ceramic or cement tile, which makes it much cheaper to transport and easier to install.

4. The Aluminum-Zinc Alloy Coated Steel offering the superior corrosion resistance.

The use of non-toxic harmless bond, the natural stone and 10 available colors enhances the environmental friendly and stylish advantage.

Technical details

| Test item | result |

| Resistance to weathering | 1000h: coating no cracks, no powder, no foam, no obvious discoloration |

| Heat resistance | 90±2℃: no obvious change |

| Cold water resistance | -40±2℃: 24h no obvious change |

| Water resistance | 240h: No foam, no no obvious change discoloration |

| UV resistance | 60℃: 1000h no obvious change |

The characteristics of colorful-stone coated metal roof tile

beautiful appearance: with the natual stone texture and strong stereoscopic sensation, and a variety of shapes, varied colors of tiles, have extremely good beautification effect the buliding

longlife time :adopt hige strength ,high corrosion resistance aluminum zinc alloy steel plate, its corrosion resistance is 3-6 times than the corrosion resistance of galvanized steel , the surface material by weathering of natural stone particles or inorganic pigments dyeing natural gravel and water-based acrylic resin, products life up to more than 30 years.

lighter weight: only equivalent material ,cement soil of 1/6, can reduce the load of the building,and it can reduce the cost of project, For the roof ,easy to transport and repeated construction and installation..

construction simole: to bending, cuting ,easy installation,simple ,low temperature season may construction

energy conservation and environment protection:the heat reflective rate is 1.4-7 times than average roofing material ,easy energy saving ,using environment protection material ,and no harm to people and environment.

PRODUCTION

Our production facility is one of the most sophisticated in the world. The teamwork between our technical and production groups has resulted in many automated systems. These systems are not just responsible for production speed, they also ensure the consistent quality of our finished goods.

Producing a coated metal tile involves four basic steps.

1. metal forming

2. coating

3. curing

4. warehousing

METAL DEPARTMENT

Large coils of Zinc-Aluminium steel are shipped into the factory. The coils are cut and formed into roof tiles and accessories.

COATING DEPARTMENT

The newly formed pieces are sent from the metal department to the coating department. Here they are coated with either high-grade roof paint, or coated in basecoat and covered in stone chips.

CURING DEPARTMENT

The newly coated pieces are then transferred to large ovens where they are baked until the coatings are fully cured and stable.

WAREHOUSING

All the cured parts and pieces are then palletized, wrapped, labeled and prepared for shipping.

QUALITY CONTROL

We employ full time professionals whose sole responsibility is testing and auditing our production process and materials. Adherence to strict guidelines maintains our foremost level of quality.

| Test Items | Reference Requirement | Method Statement |

| Water resistance | After 240 h test ,there are no cracks ,bubbles ,peeling and softening precipitation on the composite layer .And a slight color and gloss change is allowed ,compared to the untested samples . | Put in (23±2)°Cdistilled water or deionized |

| Heat resistance | After(90±2)°C,240h heat test ,there are no cracks ,bubbles ,peeling and softening precipitation on the composite layer .And a slight color and gloss change is allowed ,compared to the untested samples . | Put in constant temperature drying oven test

|

| Impact resistance | Under the height of 500mm and heavy cone quality for 1000g±1g shock ,Metal tile mineral grains no cracking and spalling phenomena | According to the standard to test the method |

| Low temperature resistance | After (-40±2)°C,24 h test , there are no cracks ,bubbles ,peeling and softening precipitation on the composite layer .And a slight color and gloss change is allowed , compared to the untested samples . | Put in refrigerator frozen test |

Alkali resistance (saturated Ca(OH)2 solution) | After 48h test,there are no cracks ,bubbles ,peeling and softening precipitation on the composite layer .And a slight color and gloss change is allowed ,compared to the untested samples . | Put in (23±2)°Csaturated calcium hydroxide solution |

Acid resistance (3%H2SO4 solution)

| After 48h test ,there are no cracks ,bubbles ,peeling and softening precipitation on the composite layer .And a slight color and gloss change is allowed ,compared to the untested samples . | Put in (23±2)°Cenvironment ,using the method of drop test |

| Freeze-thaw resistance | According to the water soak [(23°C)for 18h,(-20°C) frozen for 3h ,(50°C) hot baking 3h] for a loop. After 20 freeze -thaw cycles , there are no cracks ,bubbles ,peeling and softening precipitation on the composite layer .And a slight color and gloss change is allowed ,compared to the untested samples . | According to the water soak[(23°C)for 18h,(-20°C) frozen for 3h ,(50°C) hot baking 3h] for a loop . |

| Salt spray corrosion- resistance (Neutral salt spray test) | After 240 h test , there are no cracks ,bubbles ,peeling and softening precipitation on the composite layer .And a slight color and gloss change is allowed ,compared to the untested samples . | According to the standard to test the metho |