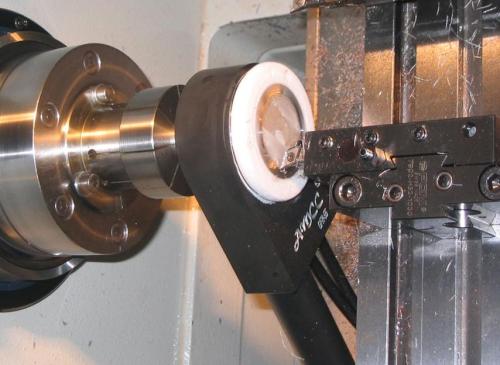

Ice clamping for rinder miller and cnc machineing

| Payment Terms: | L/C, T/T |

|---|---|

| Supply Ability: | 1 Sets Per Month |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company, Agent, Distributor/Wholesaler, Service |

Product Detail

| Model No.: | GF-250 |

|---|---|

| Means of Transport: | Air |

| Brand Name: | AMCC |

| features: | clamping of parts by icing a film of water |

| Production Capacity: | 1 Sets Per Month |

| Delivery Date: | 60 days |

Product Description

- Clamping surface: 250x150 mm (ext. dim. 367x164x73)

- Milling - Grinding - Diamond dressing

- Fixed icing plate

- Locating holes for "X Y" positioning of templates (optional)

- ''Z'' reference non-freeze key (optional)

- Steel shims for securing on magnetic plate (optional)

ADVANTAGES

any material can be clamped: metal, plastic, graphite, ceramics, honeycomb, fabric, neoprene, rubber .

parts of any shape are firmly held in place (no more specific assemblies)

stress-free clamping and unclamping, therefore no risk of distortion or breakage

high fastening power: 15 kg/cm2 on metal (by comparison, 12 kg/cm2 for magnetization, 1kg/cm2 for vacuum)

fast, freezes and thaws in seconds

release of the parts leaves no residue

increased rigidity for many materials (plastics, raw ceramics, neoprene,...) and improved surface condition

longer tool life

easy to set up, plates are compact and monoblock

operates simply with compressed air**

OPERATION

These compact and monoblock icing plates are very quickly set up:

connect the apparatus to the compressed air system

spray water onto the icing plate

position the part to be machined

operate the temp control button

within seconds the water freezes and the part is clamped

unclamping is done just as fast, by reversing the freeze/thaw valve.

As there is no water thickness under the part, z-axis repeatability depends only on the referential.

Because the plate evacuates the calories generated by machining.