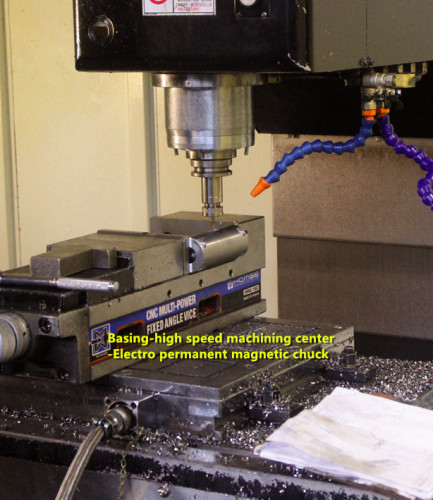

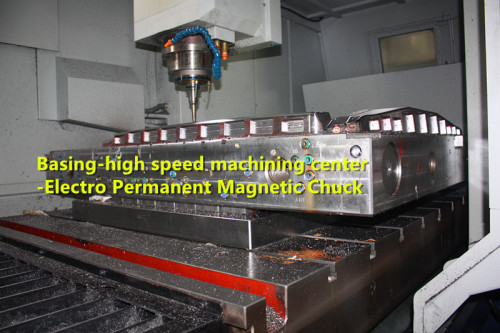

Electro Permanent Magnetic Chuck for high speed machining center

| Payment Terms: | L/C, T/T |

|---|---|

| Supply Ability: | 120 Sets Per Month |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company, Agent, Distributor/Wholesaler, Service |

Product Detail

| Model No.: | EPM75H |

|---|---|

| Processing Types: | Metal |

| Controlling Mode: | CNC |

| Brand Name: | basing |

| Use: | high speed machining center |

| Production Capacity: | 120 Sets Per Month |

| Packing: | Wooden Boxes |

| Delivery Date: | 45 days |

Product Description

Basic Info

Model NO.: EPM75HH404

Usage: Heavy Duty Clamp

Standard: Standard

Brand: Basing

Pole Number: 16 PCS

Processing: Milling &CNC Machine

Waterproof Grade: IP67

Transport Package: Wooden Boxes

Origin: China

Material: Stainless Steel

Structure: Controller

Condition: New

Pole Size: 75X75mm

Holding Force: 14-16 Kg/Cm2

Suitable Workpiece: Small and Large Workpiece

Trademark: Basing

Specification: EPM75H

Description :

1.Comprising 75mm*75mm poles with a force of 750 kgf for each pole.

2. It is possible to predetermine the force generated by counting the number of poles,

work piece gripping at least 4 pole contact faces.

3.Controller do the Magnetizing or demagnetizing in 0.5~ 5 seconds.

4.Chuck is tested for Slippering force, Waterproof test, Temperature rise test, Electrical & Demagnetizing tests

Use:

1.Used for normal and heavy duty drilling, milling, and CNC machining center

2.Best used for the workpieces at least 400*400 mm and 18 mm thick,Ideal for general pieces of various dimensions with normal operating air gaps and medium thicknesses

Standard Features and Benefits:

| 1.Flexibility Allow single set-up machining with 5- sided accessibility workpieces larger than the table are machinable | 2.Safety No electric power supply during clamping Constant and uniform magnetic power over entire area. No dispersion of magnetic flux No interference | 3.Efficient Easy and quick position, reduce set-up time | 4.Cost-effectiveness no maintenance no machine modifications reduced tool consumption |

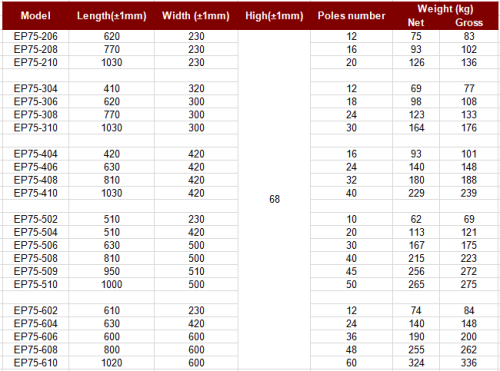

Other