Rubber Powder/granule Production plant Line

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB,CFR,CIF,EXW |

| Payment Terms: | L/C, T/T |

| Place of Origin: | Shandong |

Company Profile

| Location: | Qingdao, Shandong, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

Product Detail

| Model No.: | xk-560 |

|---|---|

| Means of Transport: | Ocean |

| Brand Name: | Eenor |

| Packing: | export packing |

| Delivery Date: | 40days |

Product Description

1.Brief Introduction:

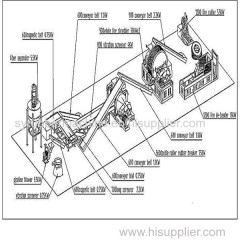

the waste tire recycling line Includs

the

Mainly machine and accessorial equipment, it is used for recycling used-tire (steel tyre and textile tyre), the final product is rubber powder,

Steel wires and nylon fibers.

2.Working flow

1.

Tyre ring cutting - 2. Ring steel separating - 3. Strips cutting - 4.

Blocks cutting - 5. rubber curshing - 6. Rubber powder screening - 7.

Magnetic steel powder separating 8. Sylon fiber separating

3.Techincal parameters:

Analysis of output

1).XKP400 rubber crusher:Output: 4500-6000kg/24 hour for about 20 mesh granule.

2).XKP450 rubber crusher:Output :7000-12000kg/24 hour for about 20 mesh granule.

3).XKP560 rubber crusher:Output : 10000-17000kg/24 hour for about 20 mesh granule.

4.Performance features:

1), iron/steel removing ratio>99.5%, fiber removing ratio>98%

2),compact structure ensure running safety, easy maintenance;

3),low energy consumption;

4),no sewage and waste gas discharge, environment protection.

5), capicity for one production line: 200-500kgs/hour

6), available finial rubber powder size: 30~120mesh.

7), adopts SIEMENS and Chinese famous brand electrical elements.