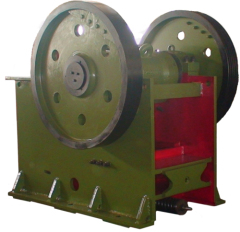

Surface installation rock jaw crusher

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB,CFR,CIF,EXW |

| Payment Terms: | Paypal, L/C, T/T, WU |

| Supply Ability: | 20-60 sets per months |

| Place of Origin: | Shanghai |

Company Profile

| Location: | Shanghai, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company, Distributor/Wholesaler |

Product Detail

| Means of Transport: | Ocean, Air, Land |

|---|---|

| Application: | Ore |

| Type: | Crusher |

| Brand Name: | MKD |

| Certificate: | ISO9001-2000; CE |

| Technology: | Welding |

| Wall thickness: | 8-10mm |

| Material of Jaw Plate: | Mn13 (High Manganese Steel) |

| Eccentric Shaft: | 45# Forged Steel |

| Production Capacity: | 20-60 sets per months |

| Packing: | In Nude or Wooden Package |

| Delivery Date: | 15-20 working days |

Product Description

The right choice for underground installations

C series jaw crushers are indisputably the most popular crushers in underground mines and quarries all around the globe. Their productivity, reliability,ease of transport and possibility to automate make them an ideal choice for operations that run 24 hours a day.

Underground assembly

Transportation of C series crushers to underground installations is greatly simplified as each major component can be handled individually, and final crusher assembly is done underground. This has a direct impact on min planning that often results in considerable time and cost savings.

Final assembly underground requires typical lifting facilities and a surprisingly short amount of time.

Easy to automate

Due to thier hydraulic setting adjustment, C series jaw crushers can be fully integrated into crushing plant automation systems. The setting of the crusher can be changed from an electrical cabinet next to the crusher, or from the operator's room, all at the touch of a button, ans even while the crusher is idling.

The lubrication of the crusher's bearings can also be automated. Bearing temperature, crusher speed and cavity levels can all be measured and fully integrated in plant automation systems.

PEC80 | PEC100 | PEC96 | PEC106 | PEC116 | PEC3045 | PEC110 | PEC125 | PEC140 | PEC145 | PEC160 | PEC200 | ||

Feed Opening width mm(in) | 800(32) | 1000(40) | 930(7) | 1060(42) | 1150(45) | 1375(54) | 1100(44) | 1250(49) | 1400(55) | 1400(55) | 1600(63) | 2000(79) | |

Feed Opening depth mm(in) | 510(20) | 760(30) | 580(23) | 700(28) | 800(32) | 760(30) | 850(34) | 950(37) | 1070(42) | 1100(43) | 1200(47) | 1500 (59) | |

Power kw(HP) | 75(100) | 110(150) | 90(125) | 110(150) | 132(175) | 160(200) | 160(200) | 160(200) | 200(250) | 200(300) | 250(350) | 400 (500) | |

Speed(rpm) | 350 | 260 | 330 | 280 | 260 | 260 | 230 | 220 | 220 | 220 | 220 | 220 | |

Product Size mm(in) | Closed Size setting mm(in) | Mtph (stph) | Mtph (stph) | Mtph (stph) | Mtph (stph) | Mtph (stph) | Mtph (stph) | Mtph (stph) | Mtph (stph) | Mtph (stph) | Mtph (stph) | Mtph (stph) | Mtph (stph) |

0-30 | 20 | ||||||||||||

0-1 1/8 | 3/4 | ||||||||||||

0-35 | 25 | ||||||||||||

0-1 3/8 | 1 | ||||||||||||

0-45 | 30 | ||||||||||||

0-13/4 | 11/8 | ||||||||||||

0-60 | 40 | 55-75 | |||||||||||

0-23/8 | 15/8 | 60-80 | |||||||||||

0-75 | 50 | 65-95 | |||||||||||

0-3 | 2 | 75-100 | |||||||||||

0-90 | 60 | 80-110 | 105-135 | ||||||||||

0-31/2 | 23/8 | 90-120 | 115-150 | ||||||||||

0-105 | 70 | 95-135 | 125-175 | 125-155 | 150-185 | 165-205 | 210-270 | 160-220 | |||||

0-41/8 | 23/4 | 110-145 | 140-190 | 135-170 | 160-205 | 180-225 | 230-295 | 175-240 | |||||

0-120 | 80 | 110-150 | 145-200 | 140-180- | 165-215 | 180-235 | 240-300 | 175-245 | |||||

0-43/4 | 31/8 | 120-165 | 160-215 | 155-200 | 185-240 | 200-260 | 260-330 | 195-270 | |||||

0-135 | 90 | 125-175 | 160-220 | 160-220 | 190-235 | 205-255 | 260-330 | 190-275 | |||||

0-53/8 | 31/2 | 140-190 | 175-240 | 175-220 | 205-260 | 225-280 | 285-360 | 215-300 | |||||

0-150 | 100 | 140-190 | 180-250 | 175-225 | 205-265 | 225-285 | 285-365 | 215-295 | 245-335 | ||||

0-6 | 4 | 150-210 | 200-275 | 195-250 | 230-295 | 245-315 | 315-400 | 235-325 | 270-370 | ||||

0-185 | 125 | 175-245 | 220-310 | 220-280 | 255-325 | 270-345 | 345-435 | 260-360 | 295-405 | 325-445 | 335-465 | ||

0-7 | 5 | 195-270 | 245-340 | 240-310 | 280-360 | 295-380 | 375-480 | 285-395 | 325-445 | 355-490 | 370-510 | ||

0-225 | 150 | 210-290 | 265-365 | 265-335 | 305-385 | 320-405 | 405-515 | 310-430 | 345-475 | 380-530 | 395-545 | 430-610 | |

0-9 | 6 | 230-320 | 290-400 | 290-370 | 335-428 | 350-450 | 445-565 | 340-470 | 380-525 | 420-580 | 435-600 | 475-670 | |

0-260 | 175 | 245-335 | 310-430 | 310-390 | 355-450 | 370-465 | 465-595 | 350-490 | 395-545 | 435-605 | 455-625 | 495-695 | 630-890 |

0-10 | 7 | 270-370 | 340-270 | 340-430 | 390-495 | 405-515 | 515-650 | 390-540 | 435-600 | 480-665 | 500-690 | 545-765 | 695-980 |

0-300 | 200 | 355-490 | 395-500 | 410-520 | 530-670 | 405-555 | 445-615 | 495-685 | 510-710 | 560-790 | 710-1000 | ||

0-12 | 8 | 390-535 | 445-560 | 460-580 | 580-740 | 445-610 | 490-675 | 545-750 | 565-780 | 615-870 | 780-1100 | ||

0-340 | 225 | 495-685 | 550-760 | 570-790 | 625-880 | 785-1105 | |||||||

0-13 | 9 | 545-750 | 605-835 | 630-870 | 685-965 | 860-1215 | |||||||

0-375 | 250 | 545-755 | 610-840 | 630-870 | 685-965 | 865-1215 | |||||||

0-15 | 10 | 600-830 | 670-925 | 695-960 | 755-1060 | 950-1340 | |||||||

0-410 | 275 | 690-950 | 745-1055 | 940-1320 | |||||||||

0-16 | 11 | 760-1045 | 820-1160 | 1030-1455 | |||||||||

0-450 | 300 | 815-1145 | 1015-1435 | ||||||||||

0-18 | 12 | 895-1260 | 1120-1575 | ||||||||||