Concrete jaw crusher aggregate

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB,CFR,CIF,EXW |

| Payment Terms: | Paypal, L/C, T/T, WU |

| Supply Ability: | 20-60 sets per months |

| Place of Origin: | Shanghai |

Company Profile

| Location: | Shanghai, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company, Distributor/Wholesaler |

Product Detail

| Means of Transport: | Ocean, Air, Land |

|---|---|

| Application: | Ore |

| Type: | Crusher |

| Brand Name: | MKD |

| Certificate: | ISO9001-2000; CE |

| Technology: | Welding |

| Wall thickness: | 8-10mm |

| Material of Jaw Plate: | Mn13 (High Manganese Steel) |

| Eccentric Shaft: | 45# Forged Steel |

| Production Capacity: | 20-60 sets per months |

| Packing: | In Nude or Wooden Package |

| Delivery Date: | 15-20 working days |

Product Description

Introduction:

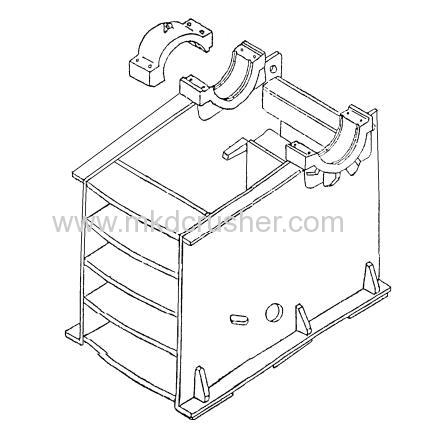

PE series jaw crusher is widely used in mining, building materials, roads, quarry, road construction railways, water and other industries. Complete product specifications , the feeding size from 150mm to1500 mm. Jaw crusher can crushing material with compressive strength of up to 300Mpa, which is a preferred primary crushing equipment for the complete set of crushing plant.

Feature:

1. High crushing ratio

2.Uniform final product

3. Simple structures

4. Reliable working performance

5. Easy to maintain

6. Low running costs

Application:

1.Jaw crusher is widely used in crushing high hardness, medium hardness materials like ore, quartz, granite, limestone, slag, building materials, marble and other soft rock and ore.

2. The maximum compressive strength of the material is up to 320MPA.

3. PE series jaw crushers are for primary crushing, PEX series jaw crushers are for secondary crushing and fine crushing.

Work principle:

The motor drives the power through the belt and drives the moving jaws around the fixed jaws of the eccentric shaft. As the jaws move upward, the angle between the bracket and the jaws increases. So moving the jaw to the fixed jaw, things will be crushed in a variety of ways. When the jaw is moved downward, the angle of the jaw crusher between the jaw jaw and the movable jaw is reduced, and the jaw of the jaw crusher moves away from the jaws by means of a lever and a spring. The product will be discharged from the jaw to the crusher.

Technical Data:

Model | Feed opening size(mm) | Max feed particle size(mm) | Adjusting range of discharge (mm) | Capacity (t/h) | Eccentric axle speed (r/min) | Motor power (kw) | Weight (t) | Dimension(mm) (L*W*H) |

PE-150x250 | 150x250 | 125 | 10~40 | 1~3 | 300 | 5.5 | 1 | 1545x1667x1330 |

PE-250x400 | 250x400 | 210 | 20~60 | 5~21 | 300 | 15 | 2.8 | 1430x1310x1296 |

PE-250x750 | 250x750 | 210 | 25~60 | 13 ~35 | 330 | 22 | 5 | 1545x1667x1330 |

PE-400x600 | 400x600 | 340 | 40~100 | 16~65 | 275 | 30 | 6.8 | 1817x1715x1591 |

PE-500x750 | 500x750 | 425 | 50~100 | 46~100 | 275 | 55 | 10.6 | 2256x1926x1865 |

PE-600x900 | 600x900 | 500 | 60~160 | 50~120 | 250 | 55 | 15.5 | 2520x1840x2320 |

PE-750x1060 | 750x1060 | 630 | 80~140 | 115~210 | 250 | 110 | 29 | 2730x2472x2840 |

PE-800x1060 | 800x1060 | 640 | 100~200 | 136~230 | 250 | 110 | 30 | 2610x2556x2800 |

PE-870x1060 | 870x1060 | 660 | 200~260 | 290~336 | 250 | 110 | 31 | 2660x2556x2800 |

PE-900x1060 | 900x1060 | 685 | 230~290 | 160~400 | 250 | 110 | 32 | 2690x2556x2800 |

PE-900x1200 | 900x1200 | 750 | 95~165 | 140~262 | 200 | 160 | 50 | 3335x3182x3025 |

PE-1000x1200 | 1000x1200 | 850 | 195~265 | 315~342 | 200 | 160 | 51 | 3435x3180x3025 |

PE-1200x1500 | 1200x1500 | 1020 | 150~300 | 400~800 | 180 | 250 | 98 | 4590x3732x3843 |

PEX-250x1000 | 250x1000 | 210 | 25~60 | 16~52 | 330 | 30 | 6.8 | 1530x1992x1380 |

PEX-250x1200 | 250x1200 | 210 | 25~60 | 20~61 | 330 | 37 | 7.9 | 1900x2192x1430 |

PEX-300x1300 | 300x1300 | 250 | 20~90 | 16~104 | 300 | 55 | 11.8 | 1720x2320x1750 |