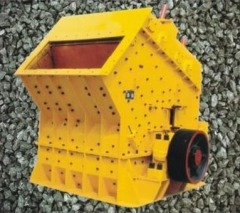

Impact Crushing Plant for limestone

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB,CFR,CIF,EXW |

| Payment Terms: | Paypal, L/C, T/T, WU |

| Supply Ability: | 20-60 sets per months |

| Place of Origin: | Shanghai |

Company Profile

| Location: | Shanghai, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company, Distributor/Wholesaler |

Product Detail

| Means of Transport: | Ocean, Air, Land |

|---|---|

| Application: | Ore |

| Type: | Crusher |

| Brand Name: | Mekind |

| Certificate: | ISO9001-2000; CE |

| Material of Main Body: | Q235 |

| Material of Hammer Plate: | Mn13Cr2 |

| Technology: | Welding |

| Upshell-opening Method: | Manual |

| Type of chamber: | Two or Three Chambers |

| Production Capacity: | 20-60 sets per months |

| Packing: | Nude and Wooden Box |

| Delivery Date: | 7-15 working days |

Product Description

Working Principle:

The impact equipment crushes materials with impact force. When the material enter the blow bar area, They are crushed due to the high-speed impact of the blow bar and are thrown to the impact plates on the rotor. Then the material will be shot back to the blow bar again for the third crush. This process repeats until the material are crushed to the required size and discharge from the lower part of the machine. The size and shape of finished powder can be changed by adjusting the gap between the impact rack and rotor support. The machine employs self-weigh security device in its back frame. When other tramp enter the impact cavity, they will be forced out the machine by impact rack in the front and back of the machine.

Our impact crushing machine has absorbed the advantage from both home and abroad. They are widely used in highways and in the areas of water conservancy, airport and civil construction and high-rise buildings, etc.

Impact crushers are ideal choice for crushing soft to middle-hard stones, this impact crusher features of reasonable structure, high capacity, safe performance, easy operation and maintenance. The most outstanding advantage of this impact crusher is that its finished particles are in good cubic shape and without any cranny.

This PF Series is capable of crushing the minerals and rocks with breaking strength up to 320Mpa, featuring with greater processing capacity and finer discharging products. The crushed minerals are in cubical shape with low flakes and no internal cracks. Therefore, this type of crusher is preferable to be selected as the equipment to get the excellent aggregate applied in highways and fields of water conservancy, airport and civil construction of high-rise buildings, etc.

Main technical parameters

Model | Sizes (mm) | Feed opening (mmxmm) | Max feeding size(mm) | Capacity (t/h) | Motor power (kw) | Weight(t) (Without Motor) | Dimension(mm) (LxWxH) |

PF-1010 | 1000x1050 | 400x1080 | 350 | 50~80 | 75 | 12.2 | 2858x2508x2470 |

PF-1210 | 1260x1050 | 400x1080 | 350 | 80~120 | 110 | 15.5 | 2690x2340x2890 |

PF-1214 | 1250x1400 | 400x1430 | 350 | 110~180 | 132 | 19 | 2690x2740x2890 |

PF-1310 | 1300x1050 | 490x1170 | 400 | 80~140 | 200 | 18.5 | 3330x2595x2862 |

PF-1315 | 1320x1500 | 860x1520 | 500 | 150~220 | 220 | 23 | 3432x3040x2862 |

PF-1316 | 1300x1600 | 800x1630 | 500 | 170~240 | 220 | 23.5 | 3432x3140x2862 |

PF-1515 | 1450x1500 | 900x1650 | 500 | 280~340 | 280 | 33 | 3950x3350x3055 |