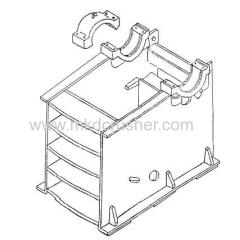

Jaw Stone Crusher with Good Quality

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB,CFR,CIF,EXW |

| Payment Terms: | Paypal, L/C, T/T, WU |

| Supply Ability: | 20-60 sets per months |

| Place of Origin: | Shanghai |

Company Profile

| Location: | Shanghai, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company, Distributor/Wholesaler |

Product Detail

| Means of Transport: | Ocean, Air, Land |

|---|---|

| Application: | Ore |

| Type: | Crusher |

| Brand Name: | MKD |

| Certificate: | ISO9001-2000; CE |

| Technology: | Welding |

| Wall thickness: | 8-10mm |

| Material of Jaw Plate: | Mn13 (High Manganese Steel) |

| Eccentric Shaft: | 45# Forged Steel |

| Production Capacity: | 20-60 sets per months |

| Packing: | In Nude or Wooden Package |

| Delivery Date: | 15-20 working days |

Product Description

Introduction of Jaw Crusher:

The Blake crusher was patented by Eli Whitney Blake in 1858. The Blake type jaw crusher has a fixed feed area and a variable discharge area. Blake crushers are of two types- single toggle and double toggle jaw crushers.

In the single toggle jaw crushers, the swing jaw is suspended on the eccentric shaft which leads to a much more compact design than that of the double toggle jaw crusher. The swing jaw, suspended on the eccentric, undergoes two types of motion- swing motion towards the fixed jaw due to the action of toggle plate and vertical movement due the rotation of the eccentric. These two motions, when combined, lead to an elliptical jaw motion. This motion is useful as it assists in pushing the particles through the crushing chamber. This phenomenon leads to higher capacity of the single toggle jaw crushers but it also results in higher wear of the crushing jaws. These type of jaw crushers are preferred for the crushing of softer particles.

In the double toggle jaw crushers, the oscillating motion of the swing jaw is caused by the vertical motion of the pitman. The pitman moves up and down. The swing jaw closes, i.e., it moves towards the fixed jaw when the pitman moves upward and opens during the downward motion of the pitman. This type is commonly used in mines due to its ability to crush tough and abrasive materials.

In the Dodge type jaw crushers, the jaws are farther apart at the top than at the bottom, forming a tapered chute so that the material is crushed progressively smaller and smaller as it travels downward until it is small enough to escape from the bottom opening. The Dodge jaw crusher has a variable feed area and a fixed discharge area which leads to choking of the crusher and hence is used only for laboratory purposes and not for heavy duty operations.

Technical Data of Jaw Crushers:

Model | Size of feed opening | Max. feed size | Capacity | Eccentric shaft rotate speed | Motor power | Closed side setting | Weight |

(mm×mm) | (mm) | (t/h) | (r/min) | (kw) | (mm) | (t) | |

PE-250×400 | 250×400 | 210 | 5-20 | 300 | 15 | 20-60 | 2.8 |

PE-400×600 | 400×600 | 340 | 16-65 | 275 | 30 | 40-100 | 6.5 |

PE-500×750 | 500×750 | 425 | 45-100 | 275 | 55 | 50-100 | 10.1 |

PE-600×900 | 600×900 | 500 | 50-120 | 250 | 55 | 65-160 | 15.5 |

PE-750×1060 | 750×1060 | 630 | 52-208 | 250 | 110 | 80-140 | 28 |

PE-800×1060 | 800×1060 | 650 | 85-228 | 250 | 110 | 100-200 | 30 |

PE-870×1060 | 870×1060 | 670 | 181-280 | 250 | 110 | 200-260 | 30.5 |

PE-900×1200 | 900×1200 | 750 | 140-320 | 200 | 132 | 95-165 | 50 |

PE-1000×1200 | 1000×1200 | 850 | 160-350 | 200 | 132 | 100-170 | 51 |

PE-1200×1500 | 1200×1500 | 1020 | 300-800 | 180 | 220 | 150-350 | 83 |

PE-1500×1800 | 1500×1800 | 1200 | 430-1000 | 160 | 355 | 220-350 | 122 |

PEX-250×750 | 250×750 | 210 | 13-35 | 330 | 22 | 25-60 | 4.9 |

PEX-250×1000 | 250×1000 | 210 | 16-52 | 330 | 30 | 25-60 | 6.5 |

PEX-250×1200 | 250×1200 | 210 | 20-60 | 330 | 37 | 25-60 | 7.7 |

PEX-300×1300 | 300×1300 | 250 | 16-104 | 330 | 55 | 20-90 | 11 |