DIN 1.2436 Cold Work Mould Steel Round Bar

| Min. Order: | 3 Ton |

|---|---|

| Payment Terms: | T/T |

| Supply Ability: | 1000 Tons/Month |

| Place of Origin: | Jiangsu |

Company Profile

| Location: | Suzhou, Jiangsu, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

Product Detail

| Model No.: | cwssteel-18 |

|---|---|

| Means of Transport: | Ocean, Land |

| cold work mould steel: | steel round bar |

| ISO: | 111262 |

| GB: | Cr12W |

| DIN: | 1.2436 |

| AISI: | D6 |

| Production Capacity: | 1000 Tons/Month |

| Packing: | Export Standard Packing or Customers′ Demand |

| Delivery Date: | 15-30 days |

Product Description

1.2436 Cold Work Mould Steel

Mechanical Property

Hot work temperature: (1) Start:1010 °C -1090°C (2) End: 930 °C

Annealing temperature: 870 °C - 900 °C

Hardness after annealing HBW: 217-255

Quenching temperature: 930 °C -950 °C

Cooling medium: oil

Tempering temperature: 200 °C - 540 °C

Hardness after tempering HRC: 61-54

Surface conditions:Black surface/ Grinded/ Machined

Characteristics:

1.2436 is for making high performance cutting, blanking tools up to 4 mm sheet thickness, woodworking tools, thread rolling dies, deep drawing and cold extrusion tools, measuring tools, scraping and trimming tools, deburing tools, moulds for abrasive plastics

Application :

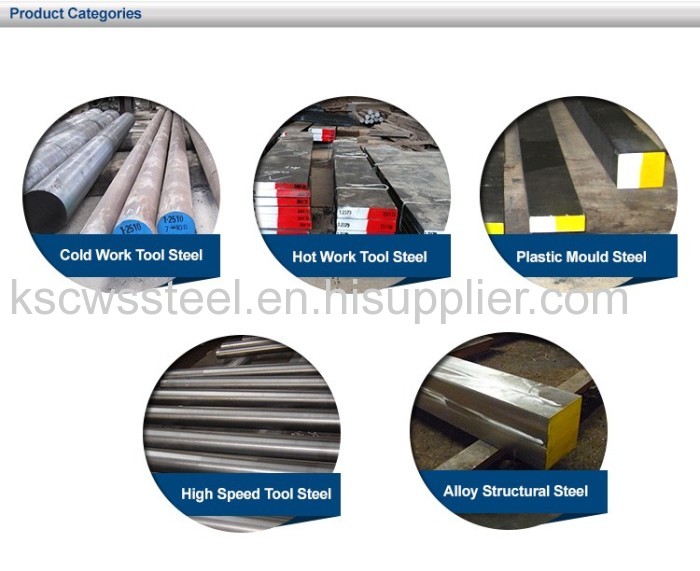

Extrusion dies and casting die for aluminium, magnesium and copper alloy. Main products include: H13, D2, D3, D6, 1.2344, 1.2379, 1.2080, 1.2436 and so on,Contact me if you need more further information!

1.Available sizes : | |

Rolled Flat bar | Rolled Round bar |

Thickness 8-60mm Width:600-610mm | dia. 50-130mm |

Forged flat bar | Forged Round bar |

Thickness:60-200mm Width:100-800mm | dia. 50-400mm |

2.Annealed hardness :≤255HBS | |

3.Properties: | |

Excellent compressive strength and good hardenability | |

High wear resistance | |

Resistance to plastic deformation | |

Cracking and chipping resistance | |