DIN 1.2311 Plastic Mould steel Plate

| Min. Order: | 3 Ton |

|---|---|

| Payment Terms: | T/T |

| Supply Ability: | 1000 Tons/Month |

| Place of Origin: | Jiangsu |

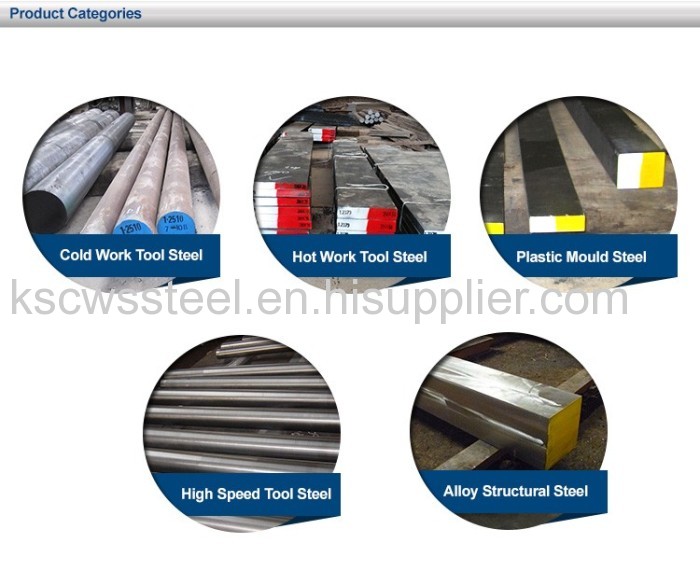

Company Profile

| Location: | Suzhou, Jiangsu, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

Product Detail

| Model No.: | cwssteel-01 |

|---|---|

| Means of Transport: | Ocean, Land |

| plastic mould steel: | steel plate |

| GB: | 3Cr2Mo |

| DIN: | 1.2311 |

| AISI: | P20 |

| ISO: | 111262 |

| Production Capacity: | 1000 Tons/Month |

| Packing: | Export Standard Packing or Customers′ Demand |

| Delivery Date: | 15-30 days |

Product Description

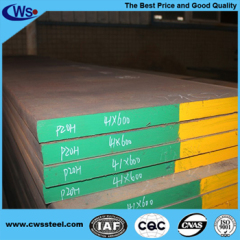

1.2311 Plastic Mould Steel

Introduction:

3Cr2Mo is an internationally widely used plastic mold steel, its good mechanical properties, high hardenability can make Larger cross-section steel to obtain more uniform hardness, and this steel has good polishing performance and high mold surface finish.

When using this steel mold, usually make quenching and tempering treatment first that the hardness is HRC28 ~ 35 (pre-hardened), and then by cold working manufactured molds can be used directly.

In this way, it can guarantee the using performance of the mould, and avoid deformation of the mold causes by heat treatment.

Therefore, the steel is suitable to manufacture big or medium-sized precision plastic mold and low melting point, tin, zinc, lead alloy die-casting molds.

Feature:

1.Pure steel vacuum degassing refining process for polishing or etch processing plastic mold

2.Pre-hardened state of supply, without heat treatment can be used directly in the mold, shorten the construction period.

3.By forging rolling processing, compact structure, 100% ultrasonic testing, non-porous, needle defects.

4.For the production of plastic mold and die casting low melting point metal mold material.

5.This steel has good machinability and mirror polishing properties.

6.Hardness:285-330HB(30-36HRC)

7.Good dimensional stability

8.With long service life,Mold die life up to 50W times

Application:

1.Main part of overloading mould

2.Thermoplastic injection molding, extrusion dies

3.Commonly used in the manufacture of TV cabinet, washing machine, refrigerator shells, buckets, etc.

Equivalent grades | GB | DIN | AISI | JIS | - | |||||

3Cr2Mo | 1.2311 | P20 | - | - | ||||||

Chemical | C | Si | Mn | Cr | P | S | Mo | Ni | - | |

0.35-0.45 | 0.20-0.40 | 1.30-1.60 | 1.80-2.10 | ≤0.030 | ≤0.035 | 0.15-0.25 | - | - | ||

Available size | Round Bar | Diameter | Length | |||||||

60-800mm | 2000-6000mm | |||||||||

Flat Bar | Thickness | Width | Length | |||||||

25-400mm | 200-800mm | 2000-6000mm | ||||||||

Smelting&shaping | EF/ ESR+ hot forged/ hot rolled | |||||||||

Surface condition | Black surface/ Grinded/ Machined | |||||||||

Annealed hardness | 50-54 HRC | |||||||||

Characteristics | good toughness properties, easy to machine, better polishability than 1.2312, | |||||||||

Applications | Plastic moulds,frames for plastic pressure dies,hydroforming tools | |||||||||

Heat Treatment | Annealing | Heat to 720÷750°Cfor 2÷4 h furnace co | ||||||||

Tempering | To be carried out after hardening in the range 580÷650°C for 25mm of thickness minimum 2h | |||||||||