PS foam fast food box making machine

| Min. Order: | 1 Set/Sets |

|---|---|

| Payment Terms: | L/C, T/T |

| Supply Ability: | according to client request |

| Place of Origin: | Shandong |

Company Profile

| Location: | Yantai, Shandong, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

Product Detail

| Model No.: | DY-1040 |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| mobile/whatsapp/wechat: | +86 13668652286 |

| skype: | jessicalv2 |

| mail: | lvlv69@hotmail.com |

| our near airport: | yantai/qingdao |

| standard: | CE |

| forming area: | 1000x1100 |

| forming speed: | 2-5seconds per stroke |

| price: | 130000usd |

| MACHINE NAME: | foam lunch box making factory |

| machine name: | ps foam fast food box machine |

| Production Capacity: | according to client request |

| Packing: | export standard |

| Delivery Date: | 30days |

Product Description

PS foam fast food box making machine

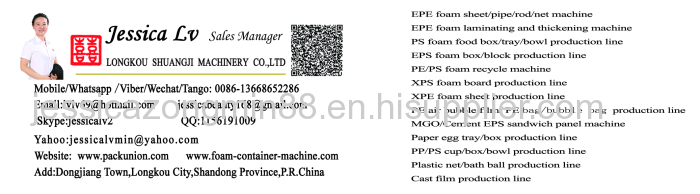

Sale Manager : jessica lv

lvlv69 at hotmail.com

jessicabeauty168 at gmail.com

Whatsapp/Viber/Wechat/Tango:0086-136 6865 2286

Skype:jessicalv2 QQ:1156191009

ICQ:634501570 YAHOO Messenger: jessicalvmin at yahoo.com

Longkou ShuangJi Machinery Co.,LTD

Longkou deyi machinery co.,ltd

Address: Dongjiang Town, Longkou City, Shandong Province, China

Machine Instruction

The PS food container machine mainly including three main parts:

1. PS foam sheet extruder: make PS foam sheet from raw material

2. Fully auto forming and cutting machine: make PS sheet to finished products, such as PS foam tray, PS foam box etc (we can design mould according to customer requirements)

3. Plastic recycle machine: recycle waste products to granules, the can mix with new material and put into PS foam sheet extruder again

A. PS Foam Sheet Extruder

PS Foam Sheet Extruder uses a tandem screw technology to produce fine-block cell-structured extruded polystyrene foam sheet with high strength and a pearl and even surface, in a continuous roll, from polystyrene injection an eco-friendly blowing gas and additives. It has a user friendly operating system with inverter controlled driving, digital temperature control and so on.

Model | Unit | PSP70/90 | PSP90/120 | PSP100/130 | PSP120/150 |

Extruder | 70/90 | 90/120 | 100/130 | 120/150 | |

Foam rate | 10-20 | 10-20 | 10-20 | 10-20 | |

Width of product | mm | 640-1040 | 640-1040 | 640-1040 | 640-1200 |

Cutting method | Single cutter | Double cutter | |||

Thickness of product | mm | 1.0-3.0 | 1.0-3.5 | 1.0-3.5 | 2.0-5.0 |

Cooling method | Cooled by wind and water | ||||

Output | kg/h | 50-90 | 100-180 | 180-230 | 230-320 |

Installed power | kw | 120 | 150 | 180 | 260 |

Dimensions(L×W×H) | m | 26×4.0×2.8 | 30×4.1×2.8 | 36×4.2×3 | 38×4.2×3.2 |

Total weight | T | 10 | 12 | 15 | 18 |

ps foam forming and cutting machine

Model | Unit | TY-1040 |

Max. forming area | mm2 | 1000×1100 |

Max. forming depth | mm | 80 |

Production efficiency | s/die | 3 - 8 |

Forming pressure | T | 15 |

Mounted power | kw | 168 |

Total weight | T | 16 |

Installation size | m | 13×2×3.2 |

plastic recycle machine

Plastic recycle and pelletizing machine is designed to reclaim the foamed polystyrene materials almost identically to new ones with its own superior filtering performance.

Structure

-- Crusher with cyclone

-- Crushed material feeding unit

-- Extrusion unit

-- T-die with screen changer

-- Cooling water bath unit

-- Pelletizing unit

-- Control panel unit

Main technical parameters

Model | Unit | DY-180+120/100 |

Screw diameter | mm | 180+120/100 |

Motor | kw | 30 |

Heater | kw | 25 |

Extruder capacity | kg/h | 80-130 |

Cooling water tank | mm | 1810×410×225 |

Granule cutting motor | kw | 2.2 |

Sale Manager : jessica lv

lvlv69 at hotmail.com

jessicabeauty168 at gmail.com

Whatsapp/Viber/Wechat/Tango:0086-136 6865 2286

Skype:jessicalv2 QQ:1156191009

ICQ:634501570 YAHOO Messenger: jessicalvmin at yahoo.com

Longkou ShuangJi Machinery Co.,LTD

Longkou deyi machinery co.,ltd

Address: Dongjiang Town, Longkou City, Shandong Province, China