High Quality 330S/350S/420S/520S Full servo automatic 100% visual inspection machine

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB,CIF,EXW |

| Payment Terms: | T/T |

| Supply Ability: | 700sets/year |

| Place of Origin: | Guangdong |

Company Profile

| Location: | Shenzhen, Guangdong, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

Product Detail

| Model No.: | AIM-330S/350S/420S/520S |

|---|---|

| Means of Transport: | Ocean |

| Plate: | Flatbed Printer |

| Type: | Flexographic Printer |

| Color & Page: | Multicolor |

| Usage: | Label Printer |

| Brand Name: | RBJ |

| dimension: | 2800x1100x1600mm |

| weight: | 1.5T |

| Max Inspect Speed: | 120M/MIN |

| Max Web Width: | 350MM |

| Max Inspect Width: | 330MM |

| Power Supply: | 3PH+N+PE |

| Max output power: | 6.7KW |

| Barometric pressure: | 0.8Mpa |

| Max Slit Speed: | 300M/MIN |

| Operating voltage: | 350v-450v AC ,50-60Hz |

| Production Capacity: | 700sets/year |

| Packing: | wooden case |

| Delivery Date: | 30 working days |

Product Description

Main features:

1. Inspection precision up to 0.02 sq. mm

2. Easy operation. Fast establishment of inspection standard template as reference for tags. The same standard template can be reused for other tags, thus to save modeling time.

3. Full featured inspection. Except common printing defects inspection, it also can be detected for bubbles, scratches and excessive glue.

4. High quality inspection efficiency. A single inspection machine is equivalent to five inspecting staffs ,which can save plenty of labor energy

5. Full servo design. Five servos are equipped with independent control, whose features include highly precision, long lifetime, maintenance-free, and easy removal of faults, etc.

6. 3D LED light source .Patented 3D LED light system ,which expands the application scope of defects detection.

7. The machine combine inspection function and high-speed slitting ,whose design show us Multi-function. Except quality inspection, this machine also has highly slitting function, whose speed up to 300m per minute.

8. Be able to fit together with other functions. Independent single/dual sided spurting platform is optional for inspection after spurting.

Options

1, Thermal transfer ribbons(TTR) digital printing device;

2,Single/double-sided spurting platform;

3,Automatic removal robot device;

4, Automatic feeding robot device;

Main components

1. Unwinding + rectification

Independent unwinding system with servo tension control; presetting of speeding cut and stop when low load; ultrasonic diagonal rectification

2. Inspection system

AIMS V3.0 Defect inspection software, high-speed line scanning camera from Canada with Ricoh lens from Japan, and 3D LED light source;

3. Paper platform

Two pneumatic buttons both at left and right , which are easy to use and in accordance with ergonomic principles;

4. Slitting unit

Two kinds of slitting knife are optional for users: round knife and cutting knife(optional);

5. Dual rewinding + rectification

Independent dual rewinding system with servo tension control; and ultrasonic diagonal rectification for orderly rewinding.

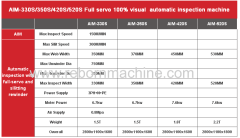

Main parameters:

| AIM-330S | AIM-350S | AIM-420S | AIM-520S | |

| Max Inspect Speed | 120M/MIN | |||

| Max Slit Speed | 300M/MIN | |||

| Max Web Width | 350MM | 370MM | 450MM | 530MM |

| Max unwind roll Dia | 750MM (29.5'') | |||

| Max rewind roll Dia | 750MM (29.5'') | |||

| Unwind mandrel Dia | 76MM(3'') or 24.5(1'') Air expanding | |||

| Rewind mandrel Dia | 76MM(3'') or 24.5(1'') Air expanding | |||

| Max Inspect Width | 330MM | 350MM | 420MM | 520MM |

| Power Supply | 3PH+N+PE | |||

| Max output power | 6.7KW | 6.7KW | 7.6KW | 7.6KW |

| Barometric pressure | 0.8Mpa | |||

| Weight | 1.5T | 1.5T | 1.8T | 2.2T |

| Overall | 2800x1100x1600 | 2800x1100x1600 | 2800x1100x1600 | 2800x1200x1800 |

| Operating voltage | 350v-450v AC ,50-60Hz | |||

| Temperature range | 0℃ to +45℃ | |||

| Max.current consumption of outputs | 18A | |||

| Typical defects (Samples) | Damaged labels,colour variations, misregistration,die-cut defects,printing dirty spots,etc. | |||