ASTM A358 Stainless Steel EFW Pipes

| Min. Order: | 500 Kilogram |

|---|---|

| Trade Term: | FOB,CFR,CIF,EXW |

| Payment Terms: | L/C, D/P, T/T |

| Supply Ability: | 2000Ton/Month |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Lishui, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

Product Detail

| Model No.: | 730640 |

|---|---|

| Means of Transport: | Ocean, Land |

| Brand: | Ganyeah |

| Grade: | SUS 304/304L/ 316L/347H/S32205/S32750 |

| Standard: | Astm a312/Astm a778/Astm a554/Astm a249/JIS G3463 |

| Inspection: | UT, ET, HT, RT |

| Section Shape: | Round |

| Certification: | API 5LC,DNV•GL, ABS, TUV, LR. |

| Length: | 6 m or as customers' request |

| Surface: | Pickling,annealing,polishing,bright |

| HS Code: | 730640000/730611000 |

| Origin: | China |

| Production Capacity: | 2000Ton/Month |

| Packing: | Plastic, Wooden Case, Others Seaworthy Packing |

| Delivery Date: | 15days |

Product Description

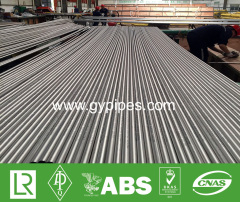

We manufacture ASTM A358 Stainless Steel EFW Pipes used in the oil, shipbuilding, power plants & natural gas industries. The SS EFW (electric-fusion-welded ) austenitic chromium-nickel stainless steel pipe/tube are suitable for corrosive or high-temperature use and for general applications .These products are tested on several chemical, physical and hydrostatic tests. It makes these to reflect paramount quality standards to maintain quality standards. The pipes come in five classes

A combination of 1600MT press brake machine, multiple rolls bending machine, welding installations for outside, inside and circumferential welding, size calibrating press& solution annealing furnace . All welders, welding operators and weld procedures are qualified to the ASME Boiler and Pressure Vessel Code.

ASTM A358 Stainless Steel EFW Pipes:

1. Standard : According to ASTM /ASME /SA312 , ASTM /ASME A213/SA213, ASTM /ASME /SA269, ASTM A249 , ASTM A279, DIN 17456-85, DIN17458-85, JISG3459, JISG3463, JISG3448, JISG3446 ETC...

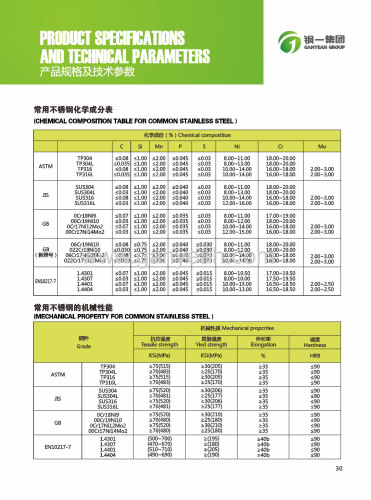

2. Material: TP304,TP304L,TP304/304L,TP304H,TP304LN,TP321,TP316,TP316L, TP316/316L, TP316Ti, TP321, TP310,TP310S,TP317L,TP347,TP347H etc.

3. Outside diameter: 8~2000mm. Wall thickness 0.5~60mm

4. Length: 1-20m random or fixed.such as 6m fixed,5-7m random etc.

5. Process Method: TIG welding,ERW welding,PAW welding,Online solution annealing.

6. Polishing: 600#,400#, 320#, 240#, 180#.etc.

7. Used for petroleum chemical, metallurgy, paper making, food, shipbuilding, environmental protection, boiler, heat exchanger , pressure container, condensator, water, electricity and so on.

8. Quality guarantee: Tubes non-destructive testing, eddy current test, ultrasonic detector, spectrum analyzer,rockwell hardness testing, tension test, metallographic microscope etc.

9. Details Including: liquid transportation pipes; gas transportation pipes;boiler tubes;structure pipes; hygeian tube. protection, boiler, heater exchanger, pressure container, condensator, water, decorative pipe,electric ,etc.

10. Packing:

Inner: bundles packing, plastic bag cover every pipe

Outer: woven bag, wooden case,steel frame,wooden frame.etc.